Designed for mobility, reliability, and continuous operation, petrol engine driven screw air compressors provide stable compressed air wherever electricity is unavailable or impractical. This article explains what a petrol engine driven screw air compressor is, how it works, and why it plays a vital role in modern field operations.

Understanding Petrol Engine Driven Screw Air Compressors

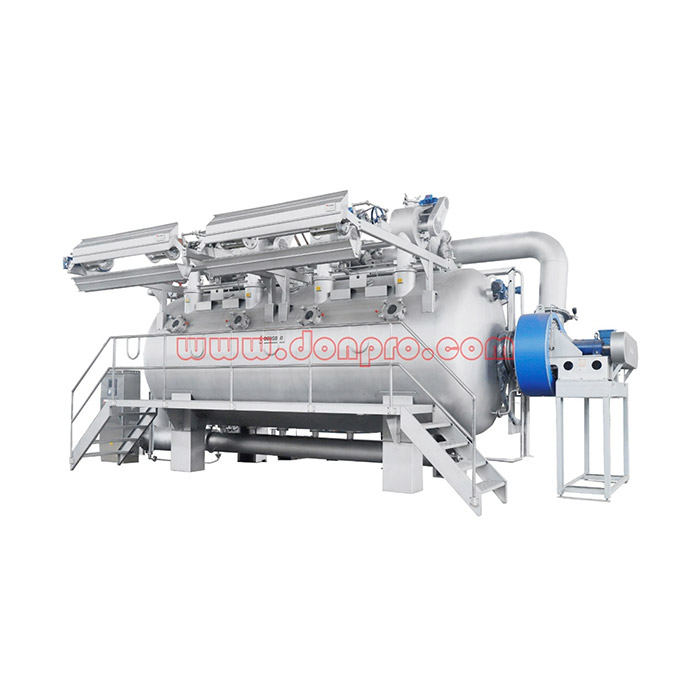

A petrol engine driven screw air compressor combines two core systems: an internal combustion petrol engine and a rotary screw air-end. Unlike piston compressors that operate in cycles, screw compressors produce air continuously, making them ideal for tools and processes that require steady airflow.

Instead of drawing power from an electrical grid, the compressor uses a petrol engine to drive the screw rotor. This design allows the unit to operate independently in remote or temporary work environments.

Manufacturers like EMAX design these compressors specifically for rugged outdoor use, ensuring stable output, efficient fuel usage, and long operating life.

How the Screw Compression Mechanism Works

At the heart of the system is the rotary screw air-end. It consists of two intermeshing helical rotors housed within a precision-machined casing.

The compression process follows three basic steps:

-

Air Intake

Ambient air enters the compressor through an intake valve and filter system designed to remove dust and debris. -

Compression

As the rotors turn, air is trapped between the rotor lobes and the housing. The volume gradually decreases as the air moves along the rotor length, raising the pressure in a smooth, continuous process. -

Discharge

The compressed air exits the air-end and flows into the air system, ready to power tools or equipment.

This continuous compression method reduces vibration, noise, and mechanical stress compared to reciprocating compressors.

Role of the Petrol Engine in the System

The petrol engine replaces the electric motor found in stationary compressors. It provides mechanical power directly to the screw air-end through belts or direct coupling.

Key advantages of a petrol engine drive include:

-

Independence from grid electricity

-

High torque output for stable operation under load

-

Rapid startup in outdoor environments

-

Suitability for mobile and trailer-mounted designs

Modern petrol engines used by manufacturers like EMAX are optimized for efficiency, durability, and ease of maintenance, even in harsh job site conditions.

Key Components and Their Functions

A petrol engine driven screw air compressor includes several integrated systems working together:

-

Petrol engine: Provides mechanical power

-

Screw air-end: Compresses air continuously

-

Cooling system: Manages heat from compression and engine operation

-

Oil separation system: Removes lubricating oil from compressed air

-

Air filtration system: Protects internal components from contaminants

-

Control panel: Monitors pressure, temperature, and operating status

Each component is engineered to support long operating hours and consistent air delivery.

Why Screw Technology Is Ideal for Field Applications

Compared to piston compressors, screw compressors offer several advantages in mobile and industrial field use:

-

Continuous airflow without pressure fluctuations

-

Higher efficiency during long operating cycles

-

Reduced wear and lower maintenance frequency

-

Quieter operation, improving job site safety and comfort

For applications such as jackhammers, sandblasting, pipeline testing, and drilling support, consistent air pressure is essential. Screw compressors deliver this reliability.

Typical Applications in Real-World Scenarios

Petrol engine driven screw air compressors are widely used across industries where mobility and reliability are critical.

Common applications include:

-

Road and bridge construction

-

Mining and quarry operations

-

Oil and gas field services

-

Infrastructure repair and maintenance

-

Emergency air supply for disaster response

-

Remote industrial installations

Because these environments often lack stable power access, petrol-driven systems remain a practical and dependable solution.

Mobility and Design Considerations

Most petrol engine driven screw air compressors are mounted on skids, frames, or towable trailers. This design allows them to be transported easily between job sites.

Features typically include:

-

Heavy-duty frames for vibration resistance

-

Weather-resistant enclosures

-

Forklift slots or trailer hitches

-

Compact layouts for easy deployment

Manufacturers like EMAX focus on balancing power output with portability, ensuring that the compressor remains easy to move without sacrificing performance.

Operational Efficiency and Reliability

Efficiency is not just about fuel consumption—it is about uptime. Screw compressors excel in applications requiring long, uninterrupted operation.

Petrol engine driven screw air compressors are engineered to:

-

Maintain stable air output over extended periods

-

Operate under varying environmental conditions

-

Reduce downtime caused by overheating or pressure loss

These characteristics make them especially valuable in time-sensitive projects where delays are costly.

Maintenance and Long-Term Use

Routine maintenance for petrol engine driven screw air compressors typically includes:

-

Engine oil and filter changes

-

Air filter inspection and replacement

-

Oil separator maintenance

-

Cooling system checks

Screw compressors generally require less frequent service than piston models, contributing to lower long-term operational disruption.

Working with established manufacturers ensures access to technical support, spare parts, and application guidance.

Choosing the Right Supplier Matters

Not all petrol engine driven screw air compressors are built to the same standards. Engineering quality, component selection, and system integration directly affect performance and reliability.

Companies seeking professional-grade solutions often work with experienced manufacturers such as EMAX, which specialize in compressors designed for demanding field applications.

Conclusion

A petrol engine driven screw air compressor is a powerful, reliable solution for applications where electricity is unavailable or impractical. By combining screw compression technology with a petrol engine drive, these systems deliver continuous airflow, high efficiency, and exceptional mobility.

Understanding how the system works—from the compression mechanism to the engine drive—helps users select the right equipment for their operational needs. For construction, mining, and industrial field operations, petrol engine driven screw air compressors remain an indispensable tool for productivity and reliability.

www.emaxpowers.com

EMAX