This is where the Multi Flow Dyeing Machine has become a key solution. Designed to optimize fabric movement, dye circulation, and process control, this advanced system plays a significant role in improving overall fabric quality while supporting efficient and sustainable production.

Understanding the Multi Flow Dyeing Machine

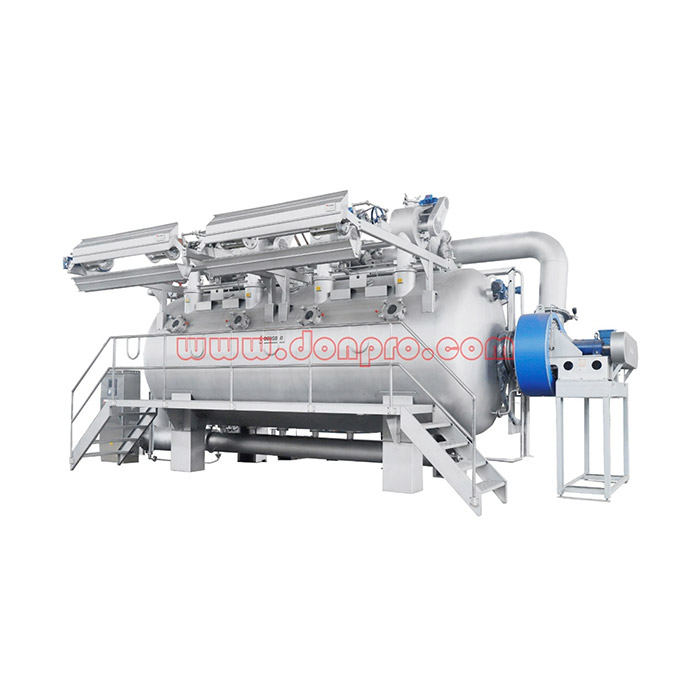

A Multi Flow Dyeing Machine is an advanced form of airflow or air-liquid flow dyeing equipment. Unlike conventional jet or overflow dyeing machines that rely primarily on liquid force, multi flow systems combine controlled airflow with optimized liquor circulation to transport fabric smoothly through the dyeing chamber.

This hybrid flow principle allows fabric to move with minimal tension while maintaining uniform exposure to dye liquor. For manufacturers working with knitted fabrics, elastic textiles, microfiber materials, or lightweight woven fabrics, this controlled movement is essential to preserving fabric integrity.

Modern systems developed by experienced manufacturers such as Dongbao Dyeing Machine focus on precise control of airflow speed, liquor ratio, and temperature distribution, ensuring repeatable results across production batches.

How Multi Flow Technology Improves Fabric Quality

Reduced Mechanical Stress on Fabric

One of the most significant advantages of multi flow dyeing technology is reduced fabric stress. Traditional dyeing machines often rely on strong hydraulic force to move fabric, which can cause abrasion, distortion, or pilling—especially on delicate materials.

By using airflow-assisted transport, the fabric “floats” through the system rather than being dragged. This significantly lowers friction between fabric and machine components, preserving surface smoothness and original fabric structure.

Improved Color Uniformity and Penetration

Consistent color is a fundamental quality requirement. Multi flow dyeing machines provide even dye distribution through optimized liquor circulation and uniform fabric movement. The combined action of air and liquid ensures that dye penetrates fibers evenly, reducing the risk of streaks, shade variation, or uneven absorption.

This is particularly important for fabrics with complex structures, such as blends or textured knits, where uneven dye uptake is more likely with traditional systems.

Enhanced Control for Lightweight and Delicate Fabrics

Lightweight fabrics are increasingly popular in fashion, sportswear, and functional textiles, but they are also more challenging to dye. Excessive tension or turbulent flow can easily deform these materials.

Multi flow dyeing machines allow operators to fine-tune airflow pressure and liquor movement according to fabric type. This adaptability ensures gentle handling while maintaining high dyeing efficiency, making the system ideal for premium fabric production.

Process Efficiency Without Compromising Quality

Lower Liquor Ratio and Better Resource Use

Many multi flow dyeing machines are designed to operate at lower liquor ratios compared to conventional dyeing equipment. Reduced water usage not only supports sustainability goals but also improves dye concentration control, which can enhance color depth and reproducibility.

Lower liquor volumes also mean faster heating and cooling cycles, improving overall process efficiency without sacrificing fabric quality.

Stable and Repeatable Dyeing Results

Consistency is critical for large-scale textile manufacturing. Multi flow systems provide stable process parameters, including temperature control, flow rate, and fabric speed. This stability minimizes batch-to-batch variation, reducing rework and quality complaints.

For brands and mills supplying international markets, repeatable quality is essential for meeting strict customer standards.

Integration into Modern Dyeing Operations

Multi flow dyeing machines are designed to integrate smoothly into modern, automated dyeing lines. Digital control systems allow operators to monitor and adjust parameters in real time, supporting data-driven process optimization.

Manufacturers focusing on airflow dyeing technology, such as Dongbao Dyeing Machine, continue to refine system designs to improve automation compatibility and long-term operational reliability.

A professional-grade Multi Flow Dyeing Machine designed for advanced textile applications can be explored in detail atMulti Flow Dyeing Machine

Applications Across Fabric Types

Multi flow dyeing machines are widely used for:

-

Knitted fabrics, including cotton, polyester, and blended materials

-

Lightweight woven fabrics requiring low tension handling

-

Functional textiles used in sportswear and outdoor apparel

-

High-end fashion fabrics where surface appearance is critical

Their flexibility makes them suitable for both small-batch production and large-scale industrial dyeing operations.

Supporting Sustainable and Clean Production Goals

Environmental compliance and clean production are increasingly important in textile manufacturing. While this article avoids pricing or regulatory claims, it is worth noting that multi flow dyeing technology inherently supports cleaner processes through reduced water usage, efficient energy transfer, and controlled chemical dosing.

By improving dye uptake efficiency, these machines can also reduce residual chemicals in wastewater, contributing to more manageable downstream treatment processes.

Why Equipment Design and Manufacturer Experience Matter

Not all multi flow dyeing machines deliver the same results. Equipment design quality, airflow system stability, and control precision all affect fabric outcomes.

Working with an experienced manufacturer ensures that the machine is engineered specifically for airflow dyeing performance rather than adapted from older designs. Dongbao Dyeing Machine focuses on airflow and air-liquid flow dyeing systems that balance fabric protection, productivity, and long-term reliability.

This expertise is especially important for customers producing high-value fabrics where quality consistency directly affects brand reputation.

Conclusion

A Multi Flow Dyeing Machine is more than an equipment upgrade—it is a strategic investment in fabric quality, process stability, and production efficiency. By combining controlled airflow with optimized liquor circulation, this technology reduces fabric stress, improves color uniformity, and supports the dyeing of delicate and lightweight materials.

For textile manufacturers seeking higher quality standards and more adaptable dyeing processes, multi flow dyeing technology offers a practical, proven solution. With experienced manufacturers like Dongbao Dyeing Machine driving innovation in airflow dyeing systems, the future of fabric dyeing continues to move toward precision, consistency, and intelligent control.

www.primerope.com

Dongbao Machinery