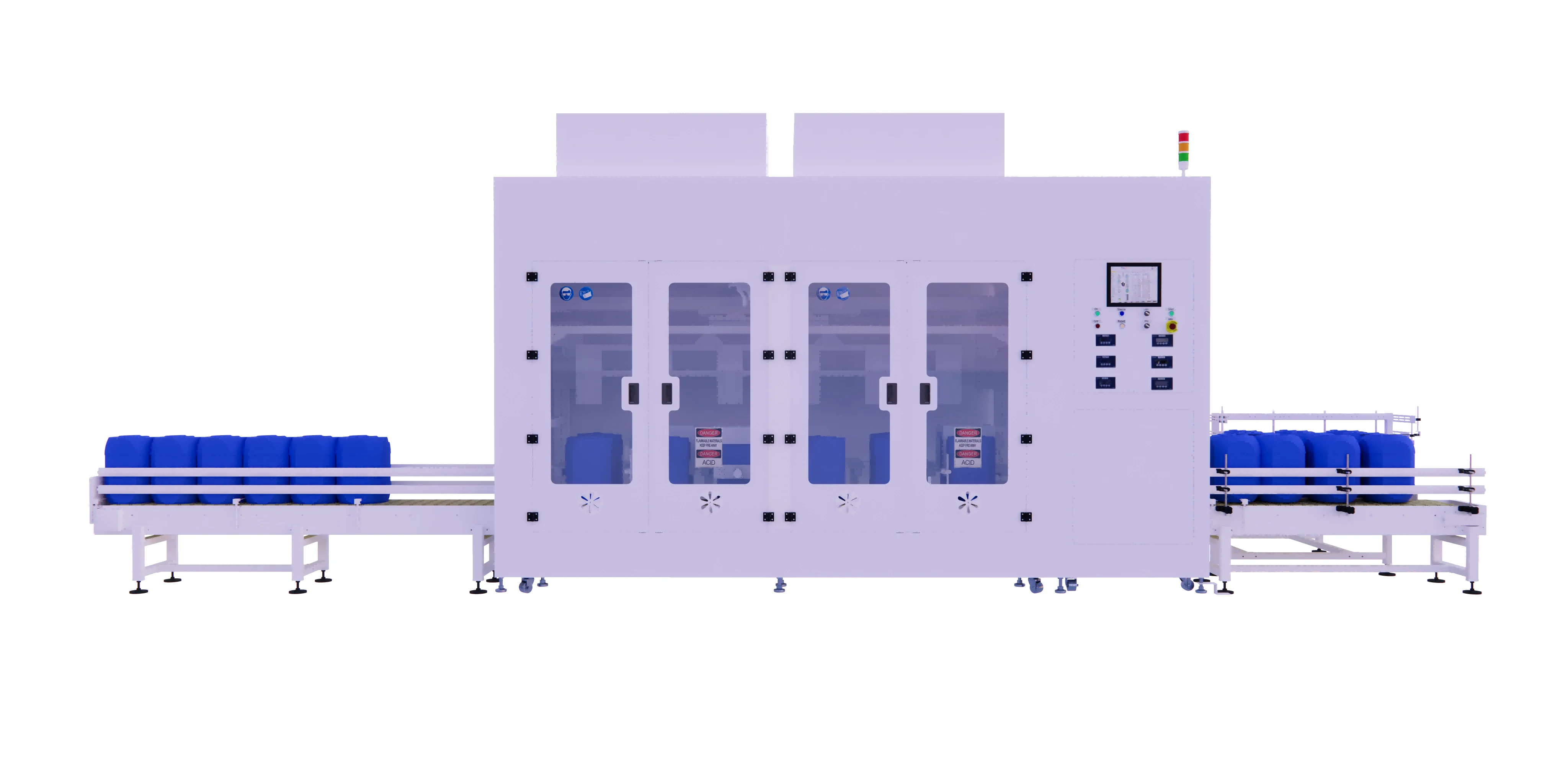

In the manufacturing and laboratory industries, efficiency and precision are essential for success—especially when operating complex equipment such as a 4L–20L automatic filling line. These machines play a crucial role in ensuring accurate, consistent, and hygienic filling of liquids into containers of various sizes. To keep them running at peak performance, proper maintenance and routine inspections are vital. In this article, we’ll explore key maintenance tips to help you maximize the efficiency, lifespan, and reliability of your filling line, drawing insights from Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd., a trusted developer and manufacturer of plastic equipment for laboratory and semiconductor industries.

1. Regular Cleaning and Sanitation

Cleanliness is the foundation of an efficient filling operation. Any residue, debris, or chemical buildup can lead to blockages, inaccurate filling, or contamination—especially in high-precision environments.

-

Clean after each production cycle. Flush the filling heads, nozzles, and pipelines using appropriate cleaning solutions.

-

Disinfect regularly. For laboratory or chemical use, ensure that all contact surfaces meet hygienic standards to prevent cross-contamination.

-

Dry thoroughly. Moisture left in the system can affect subsequent fillings and promote bacterial growth.

Companies like Xinruiwei Semiconductor Technology emphasize the importance of high-quality plastic materials and precision design in their equipment, which makes cleaning easier and more effective—helping users maintain purity and process reliability.

2. Inspect Components Routinely

Every automatic filling line consists of multiple moving parts—pumps, valves, conveyor belts, sensors, and nozzles. Even minor wear or misalignment can cause production delays or filling errors.

-

Check seals and gaskets for leaks or cracks.

-

Inspect filling heads for blockage or uneven discharge.

-

Verify sensor accuracy to ensure containers are properly positioned and filled.

-

Lubricate mechanical parts as recommended by the manufacturer to reduce friction and wear.

Using European components—as Xinruiwei does in its equipment—significantly enhances durability and operational consistency, reducing the frequency of unexpected breakdowns.

3. Calibrate Regularly for Precision

Accurate volume filling is essential for both compliance and cost control. Overfilling wastes product, while underfilling can lead to customer dissatisfaction or regulatory issues.

-

Perform calibration checks weekly or after any equipment change.

-

Use standard calibration tools or reference containers for verification.

-

Document calibration results to maintain traceability and quality control.

High-precision systems developed by Xinruiwei are designed for easy calibration and fine-tuning, ensuring consistency across production batches from prototype runs to mass production.

4. Monitor Electrical and Control Systems

Modern filling lines rely heavily on automation—using sensors, programmable logic controllers (PLCs), and touch-screen interfaces. Regular inspection of the electrical and control systems helps prevent unplanned downtime.

-

Check wiring connections for looseness or corrosion.

-

Update software and firmware when new versions are released to enhance control accuracy.

-

Test emergency stop and safety features to ensure compliance with industrial standards.

Xinruiwei’s advanced control systems are designed with both safety and stability in mind, combining European-quality components with Chinese manufacturing efficiency for optimal reliability.

5. Replace Worn Parts Proactively

Rather than waiting for a component to fail, replacing worn or aging parts early can prevent costly downtime. Keep a record of part lifecycles and establish a preventive replacement schedule.

-

Stock essential spare parts such as O-rings, sensors, and valves.

-

Track usage hours of motors and pumps for predictive maintenance.

-

Follow manufacturer guidelines on recommended replacement intervals.

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. supports its customers with personalized solutions and local supply chain reliability, ensuring that replacement parts are available quickly to minimize disruption.

6. Train Operators and Technicians

Even the best equipment won’t perform efficiently without skilled operators.

-

Provide regular training sessions on machine operation, troubleshooting, and maintenance.

-

Encourage operators to report abnormalities early.

-

Create a standardized maintenance checklist to ensure consistency.

Xinruiwei’s approach to customer support includes technical guidance and customized solutions that help users optimize both machine performance and workforce efficiency.

Conclusion

Maintaining your 4L–20L automatic filling line is not just about preventing breakdowns—it’s about sustaining long-term productivity, precision, and product quality. By cleaning regularly, inspecting components, calibrating accurately, monitoring systems, replacing parts proactively, and training staff, you can achieve optimal efficiency and extend the lifespan of your equipment.

With its combination of European-quality components, Chinese manufacturing excellence, and personalized service, Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd. exemplifies how high-performance plastic equipment can meet the demanding standards of laboratory and semiconductor industries. Following these best practices will help ensure that your automatic filling line operates smoothly, efficiently, and reliably—every single day.

www.wafera.com

Xinruiwei Semiconductor Technology (Suzhou) Co., Ltd.