With the tide of industrial automation sweeping the world, automated production line has become the core equipment for manufacturing enterprises to improve efficiency and reduce costs. As the "power center" of all kinds of equipment in the production line, switching power supply's stability, efficiency and response speed directly determine the operation efficiency of the whole production line. With its deep cultivation and innovation in the field of switching power supply, Shanghai Fengchuang Industrial Co., Ltd. has launched a series of products to empower automatic production lines with excellent performance, effectively improving production efficiency and reducing energy consumption, which has become an important boost for manufacturing enterprises to upgrade and transform.

As a national high-tech enterprise, Shanghai Fengchuang Industrial Co., Ltd. has always focused on the technological breakthrough of industrial electrical equipment since its establishment, and its "Fengyun-Fonyun" brand switching power supply has occupied a place in the market with its excellent quality. The R&D team deeply investigated the power demand of the automatic production line, and found that there are many pain points in the traditional switching power supply: in the production line where multiple devices work together, voltage fluctuation easily leads to false alarm of sensors and deviation of manipulator action; The surge current at the start-up moment may cause equipment downtime; Under long-term high-load operation, the decline of power efficiency will cause a lot of energy waste. In order to solve these problems, Fengchuang takes "stability, speed and economy" as the core goal, and creates a switching power supply solution that adapts to the automation scene.

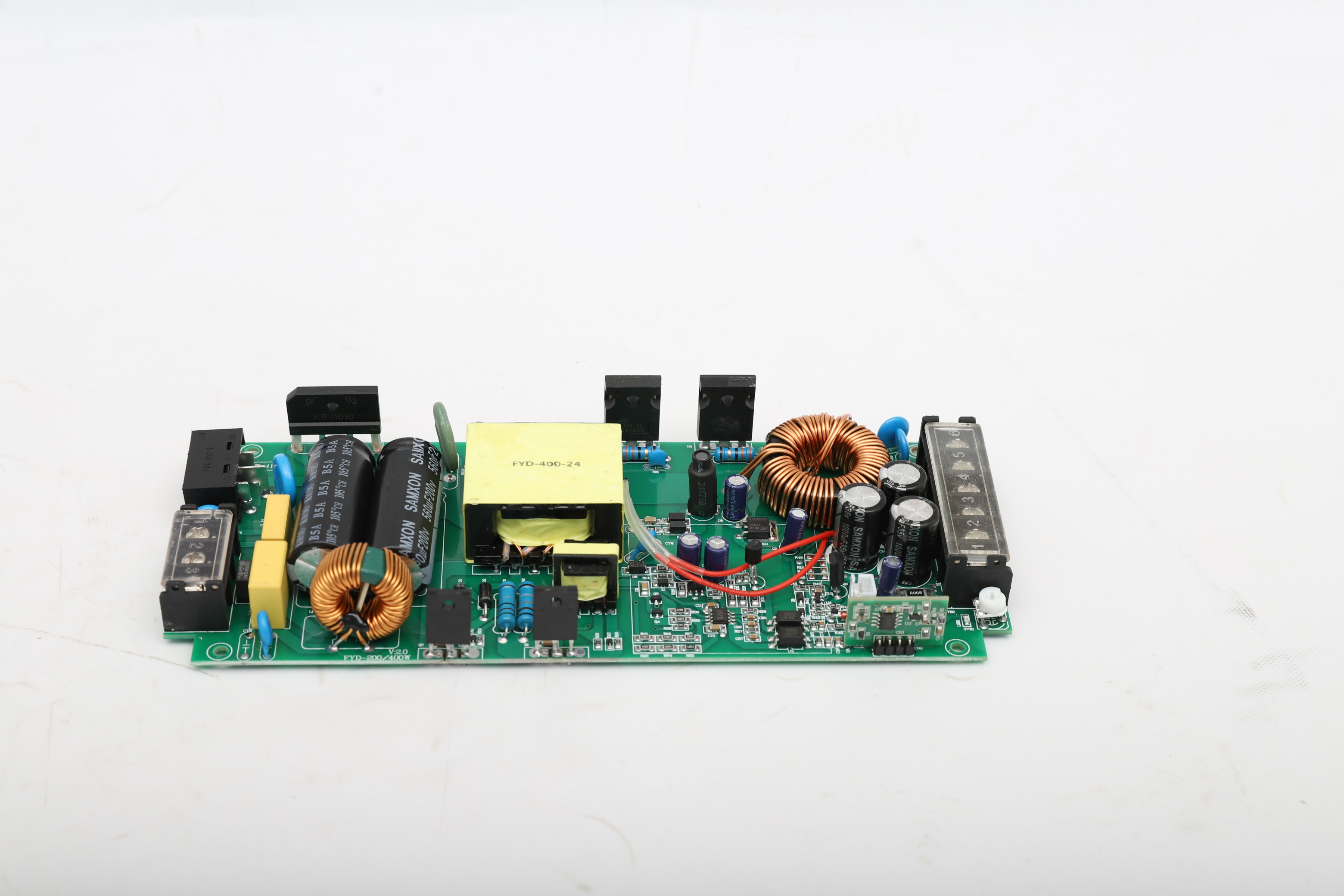

Fengchuang switching power supply has achieved a key breakthrough in stability. The double safety design of "multi-stage filtering+intelligent voltage stabilization" is adopted. The EMI filter on the input side greatly reduces the power grid interference, and the output side is equipped with a high-precision feedback circuit to control the voltage regulation rate within 0.5% and the load regulation rate within 1%. Even in the face of impact loads such as welding robots and servo motors, the output voltage fluctuation can be stabilized within 50mV. The application data of an automobile parts production line shows that after the replacement of Fengchuang power supply, the number of equipment shutdowns caused by voltage instability decreased by 72%, and the defective rate of products decreased by 1.2 percentage points.

Rapid response capability is another advantage of Fengchuang Power Supply in adapting to automation scenarios. Built-in high-speed response control chip can complete the dynamic adjustment of sudden load change within 50μs, and ensure the stable operation of equipment sensitive to power supply such as visual inspection equipment and precision assembly machinery. At the same time, the power supply supports wide voltage input (85-264VAC), which can adapt to the fluctuation of power grid in different regions, and there is no need to replace the power supply when the production line is expanded, which greatly reduces the equipment upgrade cost.

In terms of energy efficiency improvement, Fengchuang switching power supply adopts "synchronous rectification+soft switching technology", and the conversion efficiency is up to 94%, which is 8-10 percentage points higher than that of traditional power supply. Take a production line equipped with 50 devices as an example, which can save about 36,000 yuan of electricity every year. In addition, the intelligent temperature control fan is built in the power supply, which automatically stops running at low temperature, which not only reduces the noise (running noise ≤45dB), but also reduces the mechanical loss and prolongs the service life to more than 100,000 hours.

According to the needs of different automation scenarios, Fengchuang provides a wealth of customized solutions. Ultra-thin power supply designed for electronic assembly line, only 32mm thick, can be embedded in compact equipment cabinet; Waterproof and moisture-proof models developed for food packaging lines have protection grade of IP67, which can resist water mist erosion of cleaning equipment. The high-voltage power supply customized for the new energy battery production line supports multi-channel independent output to meet the voltage requirements of different processes.

In practical application, after the introduction of Fengchuang switching power supply into the intelligent assembly line of a home appliance enterprise, the overall operation efficiency of the production line has increased by 18%, and the overall equipment efficiency (OEE) has increased from 65% to 82%, and the annual added output value has exceeded 20 million yuan. The production director of the enterprise commented: "Fengchuang Power not only solved the problem of downtime that has plagued us for a long time, but also helped us achieve the certification goal of green factory."

At present, Fengchuang switching power supply has passed many certifications such as CE, UL and CCC, and is widely used in automatic production lines in automobile manufacturing, 3C electronics, medical devices and other fields. In the future, Fengchuang will continue to integrate digital twinning and Internet of Things technologies, develop intelligent power supply with remote monitoring and predictive maintenance functions, help automated production lines move towards "more efficient, smarter and greener", and inject sustained impetus into the high-quality development of China manufacturing industry.

www.fonchuang.com

Shanghai Fonchuang Industrial Co.,Ltd.