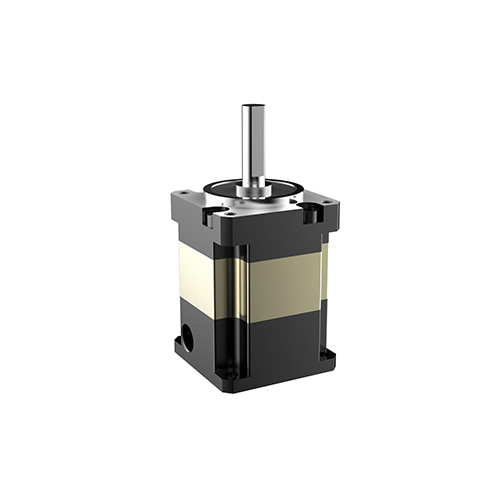

Planetary gear reducers are a cornerstone of modern automation systems, prized for their compact design, high torque transmission, and efficiency. Selecting the right planetary reducer for your application is critical—not only for system performance but also for the longevity and reliability of your machinery.

In this article, we’ll walk through the key considerations for selecting planetary reducers, including sizing, mounting configurations, and lubrication strategies. We'll also highlight how Suzhou Yijiaang Automation Technology Co., Ltd., a company specializing in transmission component applications, development, sales, and technical support, can support your success in automation.

What Is a Planetary Reducer?

A planetary reducer (or planetary gearbox) is a type of gear system that uses a central sun gear, planet gears, and a ring gear to transmit torque. This arrangement offers:

High torque density

Compact size

Low backlash

High efficiency (up to 97%)

Coaxial input/output configuration

These features make planetary reducers ideal for robotics, CNC machinery, packaging, printing, and automation systems.

Sizing the Right Planetary Reducer

Choosing the correct size is the foundation of optimal performance. Here's what to consider:

a. Torque Requirements

Start with the continuous and peak torque demands of your application. Always select a reducer with a rated output torque comfortably above your application’s continuous torque.

Tip from Suzhou Yijiaang: Choose a safety factor of 1.5–2.0 for dynamic loads or applications with frequent start-stops.

b. Gear Ratio

The reduction ratio determines how much the input speed is reduced and torque is multiplied. Typical planetary reducer ratios range from 3:1 to 100:1, available in single or multi-stage configurations.

Use lower ratios (3:1–10:1) for high-speed, low-torque applications.

Use higher ratios for high-torque, precision-demanding operations.

c. Input Speed

Check the maximum input speed rating. Most standard reducers handle 3000–6000 RPM; exceeding this can lead to overheating or premature wear.

d. Backlash

Backlash is the angular play between gear teeth. For high-precision motion control (e.g., robotics or CNC), aim for low-backlash models (≤5 arcmin).

Mounting Considerations

Proper installation is crucial for long-term stability and efficiency. Consider the following:

a. Input Connection

Planetary reducers typically connect to motors via:

Clamp-style input (shaft-coupled)

Flange-mounted motor adapters

Ensure compatibility with your motor shaft size, flange dimensions, and keyways.

b. Output Mounting

The output can be:

Shaft-style (keyed or smooth)

Flange-mounted

Hollow shaft with shrink disc

Yijiaang Advantage: They offer a wide range of standard and custom mounting solutions tailored to various servo and stepper motors.

c. Installation Orientation

Although planetary reducers are generally position-insensitive, vertical installation may require additional lubrication considerations to prevent dry spots or oil starvation.

Lubrication & Maintenance Tips

Lubrication is essential for smooth operation and long service life.

a. Lubricant Type

Most planetary gearboxes use:

Synthetic gear oils (ISO VG 220/320)

Lithium-based grease for life-lubricated models

Check the manufacturer’s specifications.

b. Lubrication Method

There are three common methods:

Grease-filled: Maintenance-free, sealed design

Oil-filled with drain plug: Allows for periodic oil changes

Oil bath with circulation: For heavy-duty, continuous use

c. Maintenance Schedule

Check for leaks, unusual noise, or overheating regularly.

Replace oil every 3000–5000 hours, unless it's a sealed unit.

Ensure proper ventilation if operating in high-speed or enclosed conditions.

Yijiaang Tip: Keep a service log and integrate lubrication checks into your preventive maintenance cycle.

Yijiaang : Your Partner in Precision Power Transmission

With years of industry experience, Suzhou Yijiaang Automation Technology Co., Ltd. is a trusted supplier and technical service provider of gear reducers, couplings, linear modules, and transmission components.

Why Choose Yijiaang?

Application Expertise: Yijiaang engineers help match the right reducer to your motion system requirements.

Product Range: From compact planetary gearboxes to heavy-duty cycloidal reducers.

Customization Services: Tailored flange, shaft, and mounting options for OEM projects.

After-Sales Support: Technical guidance, sizing tools, and customer-focused service.

Whether you're building a precision robotic arm or automating industrial conveyors, Yijiaang provides reliable, durable, and high-performance drive solutions to power your automation vision.

Final Thoughts

Choosing the right planetary reducer isn’t just about torque—it's about the whole system: speed, precision, installation, lubrication, and long-term durability. A well-selected and maintained gearbox will dramatically improve your machine’s efficiency and service life.

By partnering with an expert supplier like Suzhou Yijiaang Automation Technology Co., Ltd., you get not only high-quality components but also the technical support to make informed, confident choices.

Planetary Gearboxes in Industry: Uses, Benefits, and Technical Insights

www.yijiaangreducers.com

Suzhou Yijiaang Automation Technology Co., Ltd.