In recent years, PC cold water kettles have become a staple product in household, hospitality, and foodservice markets worldwide. Their durability, transparency, and modern appearance make them a popular alternative to glass or low-grade plastic pitchers. For importers and distributors, sourcing PC cold water kettles at wholesale scale requires more than just comparing catalogs. Material quality, manufacturing capability, compliance standards, and long-term supplier reliability all play a critical role.

Understanding PC Material and Its Advantages

PC, or polycarbonate, is a high-performance plastic known for its impact resistance, clarity, and heat tolerance. In cold water kettles, PC offers several practical advantages:

High transparency similar to glass, suitable for modern kitchen aesthetics

Strong resistance to cracking or shattering during transport and daily use

Lightweight compared to glass, reducing logistics risk

Stable performance across temperature changes, especially for refrigerated use

For importers targeting mid- to high-end consumer markets, PC cold water kettles often strike a balance between durability and visual appeal.

However, not all PC materials are equal. Importers should verify whether the manufacturer uses virgin PC or recycled blends, and whether the material complies with food-contact safety regulations in the destination market.

Key Product Features Importers Should Evaluate

When buying PC cold water kettles wholesale, focusing only on appearance can lead to long-term issues. Practical evaluation should include:

Lid and Pouring Design

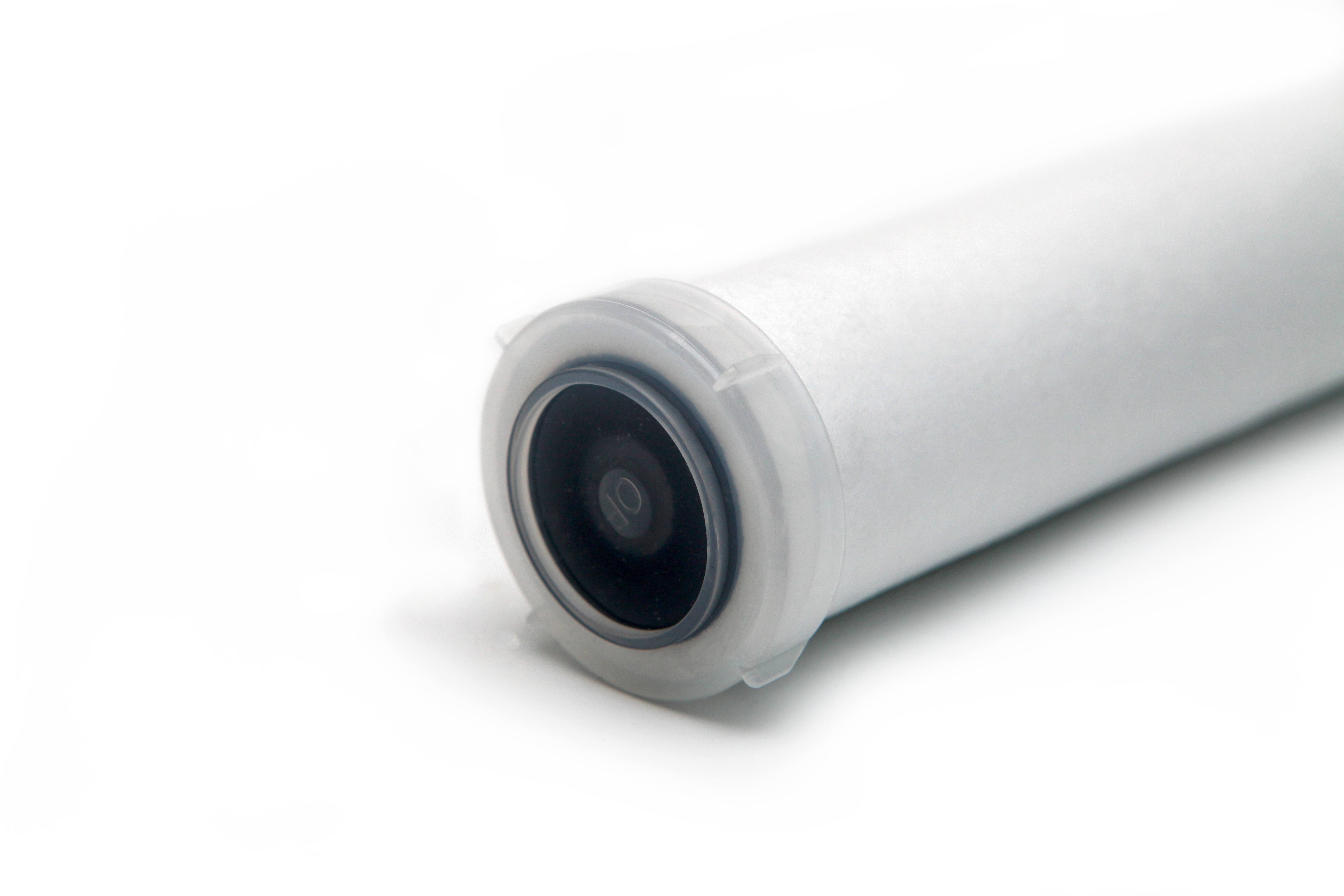

A well-designed lid is essential for user experience. Look for secure-fit lids with smooth pouring spouts that prevent dripping. Some designs include dust-proof flip lids or silicone sealing rings to improve functionality.

Wall Thickness and Structural Strength

Uniform wall thickness improves durability and reduces the risk of stress cracks over time. Thin walls may lower manufacturing costs but often lead to higher defect rates during shipping or customer use.

Handle Ergonomics

Handles should be comfortable, securely attached, and balanced when the kettle is full. Importers supplying to hospitality or family-use markets should pay special attention to this detail.

Capacity Range

Offering multiple capacity options allows distributors to serve different customer segments, from personal use to restaurant service. Manufacturers with flexible mold capabilities are better suited for long-term cooperation.

Compliance and Certification Considerations

For importers, compliance is non-negotiable. PC cold water kettles intended for food and beverage use must meet regulatory standards depending on the target market.

Common compliance requirements include:

Food-grade material certification

Migration testing for food contact safety

BPA-related compliance statements (even if PC contains BPA, documentation must be clear and accurate)

Factory quality management systems such as ISO

Working with a manufacturer experienced in export markets reduces the risk of customs delays and regulatory disputes.

Manufacturing Capability and Customization

One of the biggest advantages of sourcing directly from a professional plastic products manufacturer is customization capability. Importers should assess:

Mold development experience

Logo printing or embossing options

Color customization for lids or handles

Packaging customization for retail or bulk shipment

Quality Control in Bulk Orders

Even well-designed products can fail without proper quality control. Importers should confirm whether the supplier has:

Incoming raw material inspection

In-process quality checks

Finished product inspection before packing

Drop testing or leak testing procedures

Requesting pre-shipment inspection reports or arranging third-party inspections is a common practice for bulk PC kettle orders.

Packaging and Logistics Practicalities

PC cold water kettles are lightweight but bulky. Efficient packaging design helps reduce damage and optimize container space. Importers should discuss:

Individual protective packaging

Master carton stacking strength

Palletization options

Container loading plans

Experienced exporters can often suggest packaging improvements that lower breakage rates without increasing material waste.

Choosing the Right Supplier Partner

Beyond product specifications, supplier reliability matters just as much. A long-term partner should demonstrate:

Consistent production capacity

Stable raw material sourcing

Clear communication in English

Experience serving international clients

Kaisheng, as a manufacturer focused on plastic products, understands the importance of combining material expertise with export-oriented production processes. For importers, working with a supplier that views cooperation as a partnership rather than a transaction helps build sustainable business growth.

Market Trends and Practical Positioning

PC cold water kettles are not novelty items. They are everyday products with steady demand across multiple regions. Importers can position them effectively by:

Targeting home organization and kitchen storage trends

Supplying hotels, cafes, and catering businesses

Bundling kettles with other plastic drinkware products

Rather than chasing short-term trends, focusing on functional design and consistent quality helps build repeat orders.

Final Thoughts

Wholesale sourcing of PC cold water kettles is a strategic decision that impacts product reputation, logistics efficiency, and customer satisfaction. By understanding material performance, evaluating manufacturing capability, and choosing experienced suppliers, importers can reduce risk and improve long-term profitability.

A grounded approach—focused on real product performance and supplier reliability—will always outperform surface-level sourcing decisions.

www.czksplastic.com

Kaisheng