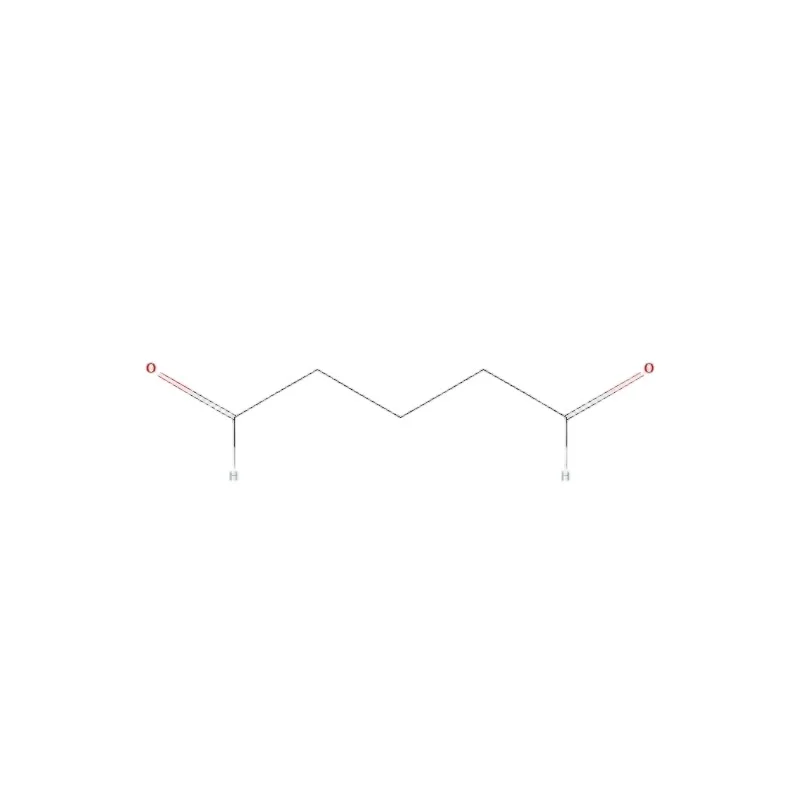

Glutaral, also known by its chemical synonyms Glutaraldehyde, Glutaric dialdehyde, or Pentanedial, has become a cornerstone in industrial, medical, and laboratory sterilization processes. With a molecular formula of C5H8O2 and CAS number 111-30-8, this high-efficiency biocide offers reliable antimicrobial action while minimizing environmental and health risks. In this blog post, HBWK, as high quality fine chemicals manufacturing factory, will share information about glutaral disinfectant solution for industrial and medical applications.

Industrial Applications of Glutaral Disinfectant Solution

In industrial settings, Glutaral (Glutaraldehyde, C5H8O2) is widely used for surface sterilization and equipment maintenance. Industrial-grade glutaral disinfectant solutions, available in 25% and 50% concentrations, provide exceptional stability under high-load operations, including water treatment systems, chemical plants, and food processing lines.

One advantage of using glutaral in these environments is its chemical robustness: even under repeated application or fluctuating temperatures, Glutaric dialdehyde maintains effective microbial control. Modified glutaral formulations can also be combined with other biocides to improve sterilization outcomes without introducing additional toxicity or environmental concerns.

Pharmaceutical and Laboratory Uses

Pharmaceutical environments demand stringent sterilization standards, making Pharma-grade glutaral (Glutaraldehyde, CAS 111-30-8) an ideal solution. Its low toxicity, reduced methanol content, and predictable efficacy allow safe use in cleanrooms, laboratory benches, and production equipment.

In practice, glutaral disinfectant solution is often integrated into multi-step sterilization protocols. It can act independently or synergistically with other disinfectants, enabling high-efficiency microbial reduction in critical areas. For laboratory operators, the precision and stability of Pentanedial (C5H8O2) allow consistent sterilization outcomes, reducing downtime and maintaining regulatory compliance.

Food Safety and Glutaral Applications

Food-grade glutaral disinfectant solution plays a key role in maintaining hygiene standards in food processing. With 25% and 50% concentrations, food-grade glutaral ensures safe disinfection on surfaces that may contact consumables. Its biodegradability and low environmental impact make it a preferred choice over traditional aldehyde disinfectants such as formaldehyde.

The unique chemical structure of Glutaric dialdehyde (C5H8O2) allows effective microbial inactivation while preserving surface integrity. Its compatibility with stainless steel, plastics, and glass makes it practical for diverse processing equipment, enabling streamlined cleaning protocols without compromising safety.

Environmental and Safety Advantages

Compared with older sterilizers, glutaral (Glutaraldehyde, Pentanedial) stands out for its environmentally conscious profile. Its biodegradability reduces contamination risks in water and soil, while the low toxicity and minimal methanol content lower occupational hazards for staff.

Chemical safety is further supported by clear handling guidelines: storing glutaral in cool, dry conditions and avoiding incompatible substances ensures long-term stability of C5H8O2-based solutions. Operators report that these precautions, combined with personal protective equipment, make glutaral safer and more manageable than many other aldehyde disinfectants.

Optimizing Disinfection Protocols with Glutaral

Practical experience shows that the effectiveness of glutaral disinfectant solution depends on concentration, contact time, and surface type. For high-risk areas, 50% industrial or pharma-grade solutions provide rapid microbial reduction. Routine cleaning can be handled with 25% formulations, balancing safety, cost, and efficiency.

Glutaraldehyde (C5H8O2) also integrates well with other disinfectants. Synergistic protocols combining glutaral with quaternary ammonium compounds or hydrogen peroxide can tackle resistant biofilms and difficult-to-sterilize surfaces, extending the disinfectant’s applicability across complex industrial or laboratory challenges.

Long-Term Benefits of Glutaral-Based Solutions

Using glutaral over time provides operational and microbial management advantages. Facilities report reduced contamination, longer equipment life, and predictable sterilization outcomes. Modified glutaral formulations enhance surface adherence and targeted microbial control, allowing long-term integration into disinfection schedules.

Furthermore, Pentanedial (CAS 111-30-8)’s chemical stability minimizes the frequency of reapplication, while its low toxicity profile ensures minimal cumulative exposure risk, supporting safer workplaces.

Handling and Storage Considerations

Despite its lower toxicity, proper handling of glutaral (Glutaraldehyde, Glutaric dialdehyde) remains essential. Concentrated solutions should be stored in cool, shaded areas and kept away from reactive chemicals. Personnel handling glutaral are advised to use gloves and eye protection, particularly when preparing or applying concentrated 50% solutions.

For combination protocols, adherence to manufacturer guidelines prevents unintended chemical interactions and maintains C5H8O2 solution effectiveness. Routine personnel training in handling, application, and neutralization ensures both safety and optimal disinfection performance.

Comparative Advantages Over Traditional Disinfectants

Compared with formaldehyde and ethylene oxide, glutaral (Glutaraldehyde, Pentanedial) offers multiple advantages:

-

Lower toxicity and reduced methanol content for safer handling

-

High compatibility with a wide range of surfaces and biocides

-

Reliable biodegradability, minimizing environmental impact

-

Multiple grades (industrial, pharma, food) for tailored applications

These factors make glutaral a versatile solution for standardized sterilization across industries, simplifying chemical management while maintaining consistent performance.

Future Trends in Glutaral Disinfection

As environmental standards tighten and demand for safe sterilization grows, glutaral disinfectant solutions are positioned for expanded adoption. Innovations in modified glutaral formulations (C5H8O2) will enhance efficacy against resistant pathogens while maintaining low ecological footprint. Automation and integration into continuous sterilization lines are likely to increase, reflecting a shift toward high-efficiency, low-toxicity disinfection.

Combination protocols using Glutaraldehyde, Glutaric dialdehyde, or Pentanedial will continue to evolve, offering multi-functional sterilization strategies. This flexibility underscores glutaral’s role as both a reliable disinfectant and a sustainable chemical solution for diverse applications.

Conclusion

Based on extensive operational experience, glutaral disinfectant solution (CAS 111-30-8, C5H8O2) proves to be a safe, versatile, and highly effective sterilizer. Its multiple concentrations and grades provide tailored solutions for industrial, pharmaceutical, and food-related applications.

Long-term benefits include improved microbial control, reduced equipment contamination, and safer handling conditions. By incorporating glutaral, Glutaraldehyde, Glutaric dialdehyde, or Pentanedial into routine disinfection strategies, operators can achieve efficient, reliable, and environmentally responsible sterilization across a wide range of sectors.

www.dico-hbwk.com

HBWK