In the ever-evolving world of manufacturing, 3D printing has emerged as a revolutionary technology, transforming how we design, prototype, and produce parts. From rapid prototyping to end-use production, 3D printing offers unparalleled flexibility, precision, and efficiency. In this guide, we’ll explore the materials, applications, and benefits of 3D printing parts, with a special focus on how Linkwork Precision Machinery integrates this technology with traditional CNC machining to deliver cutting-edge solutions for industries ranging from automotive to aerospace.

Materials for 3D Printing Parts

The choice of material is critical in 3D printing, as it directly impacts the performance, durability, and functionality of the final product. Here are some of the most commonly used materials in 3D printing:

-

Plastics (PLA, ABS, PETG): Ideal for prototyping and lightweight applications, these materials are cost-effective and easy to print.

-

Nylons (PA6, PA12): Known for their strength and flexibility, nylons are often used in functional parts and industrial applications.

-

Metals (Aluminum, Titanium, Stainless Steel): Metal 3D printing is perfect for high-strength, heat-resistant components used in aerospace, automotive, and medical industries.

-

Resins (Standard, Tough, Flexible): Resins offer high detail and smooth finishes, making them suitable for intricate designs and dental or jewelry applications.

-

Composites (Carbon Fiber, Glass-Filled): These materials combine the strength of fibers with the versatility of polymers, ideal for lightweight yet durable parts.

At Linkwork Precision Machinery, we leverage advanced 3D printing technologies to work with a wide range of materials, ensuring that every part meets the highest standards of quality and performance.

Applications of 3D Printing Parts

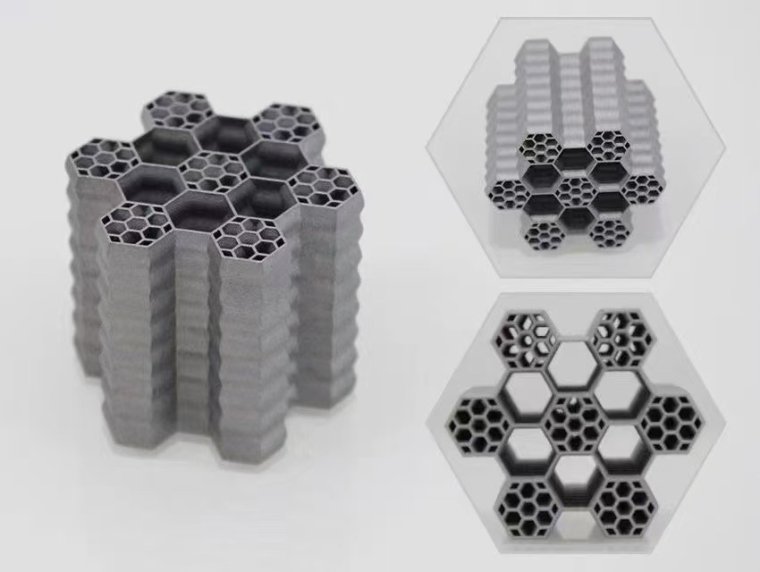

3D printing has found its way into nearly every industry, thanks to its versatility and ability to produce complex geometries that traditional manufacturing methods cannot achieve. Here are some key applications:

-

Automotive: From custom car parts to lightweight components, 3D printing enables faster prototyping and production of high-performance parts.

-

Aerospace: The aerospace industry benefits from 3D-printed components that are both lightweight and strong, reducing fuel consumption and improving efficiency.

-

Medical: Custom prosthetics, implants, and surgical tools are now being 3D printed to meet patient-specific needs.

-

Electronics: 3D printing allows for the creation of intricate housings, connectors, and heat sinks for electronic devices.

-

Industrial Automation: Custom jigs, fixtures, and robotic components can be quickly produced to streamline manufacturing processes.

Linkwork Precision Machinery specializes in combining 3D printing with traditional CNC machining to deliver tailored solutions for these industries. Whether it’s a prototype or a production-ready part, we ensure precision and reliability.

Benefits of 3D Printing Parts

The advantages of 3D printing are numerous, making it a game-changer in modern manufacturing:

-

Design Freedom: 3D printing allows for the creation of complex geometries that are impossible with traditional methods.

-

Rapid Prototyping: Speed up the development process by quickly iterating and testing designs.

-

Cost-Effectiveness: Reduce material waste and tooling costs, especially for low-volume production.

-

Customization: Easily produce customized parts tailored to specific requirements.

-

On-Demand Manufacturing: Produce parts as needed, reducing inventory costs and lead times.

By integrating 3D printing with our CNC machining, Linkwork Precision Machinery offers a seamless blend of innovation and precision, ensuring that our clients receive the best of both worlds.

Why Choose Linkwork Precision Machinery?

At Linkwork Precision Machinery, we pride ourselves on being a one-stop solution for all your precision manufacturing needs. Our expertise in CNC machining, including CNC milling, turning, and sheet metal fabrication, combined with our advanced 3D printing capabilities, allows us to deliver high-quality, custom parts for a wide range of industries.

Whether you’re in the automotive, aerospace, medical, or electronics sector, we have the tools and expertise to bring your ideas to life. Our commitment to quality, precision, and customer satisfaction sets us apart as a trusted partner in the manufacturing industry.

Conclusion

3D printing is no longer just a futuristic concept—it’s a practical, efficient, and innovative solution for modern manufacturing. By understanding the materials, applications, and benefits of 3D printing, businesses can unlock new possibilities and stay ahead of the competition.

At Linkwork Precision Machinery, we’re dedicated to helping our clients harness the power of 3D printing and CNC machining to achieve their goals. Contact us today to learn more about how we can support your next project with cutting-edge technology and unparalleled expertise.

www.szlinkwork.com

Shenzhen Linkwork Precision Machinery Co., Ltd.