https://www.gwinsys.com/The-Structure-of-a-New-Energy-Drive-Motor-Assembly-Line.html

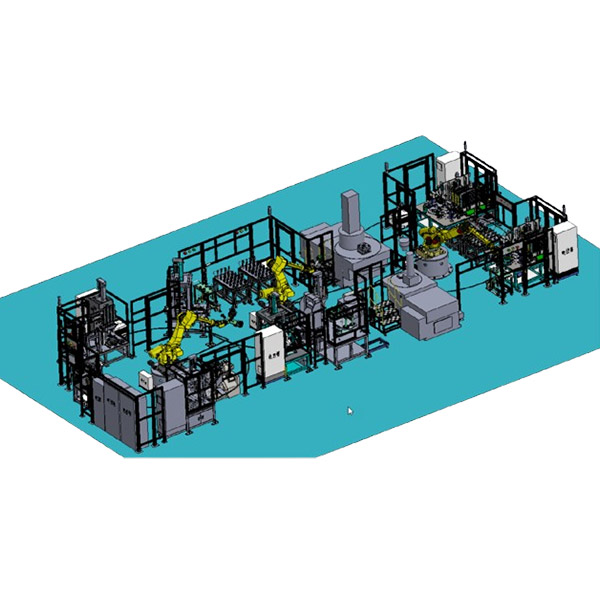

The rise of new energy vehicles has placed increasing importance on the precision and efficiency of motor production. At the heart of every electric vehicle lies the new energy drive motor, a highly sophisticated component that converts electrical energy into mechanical motion. The assembly line responsible for building these motors plays a critical role in ensuring reliability, safety, and performance. Jieyun Intelligent Equipment (Suzhou) Co., Ltd. specializes in advanced assembly line solutions that streamline the production of new energy drive motors, meeting the growing demands of the global electric vehicle industry.

Core Components of a New Energy Drive Motor

A new energy drive motor is not a single piece of equipment but the result of a carefully orchestrated assembly of multiple precision parts. Key components include:

-

Stator – The stationary part of the motor, consisting of windings and laminated steel cores, responsible for generating a rotating magnetic field.

-

Rotor – The rotating element inside the stator, which converts magnetic force into mechanical torque.

-

Motor Housing – The protective casing that secures internal components and ensures structural integrity.

-

Connectors – Electrical connectors that enable stable power input and communication with external systems.

-

Encoder – A critical sensor device that monitors motor speed and position, ensuring accurate control in electric vehicle operation.

-

Controller – Often considered the “brain” of the system, the controller regulates voltage, current, and frequency to optimize motor efficiency and performance.

Together, these elements create a system capable of delivering powerful, precise, and energy-efficient performance—essential qualities for new energy vehicles.

The Role of the Assembly Line

A new energy drive motor assembly line is designed to bring together these components in a highly efficient and error-free process. Modern lines integrate advanced automation technologies to guarantee precision and consistency at every stage.

Key functions of the assembly line include:

-

Component preparation and handling – Automated feeders and robotic arms ensure stators, rotors, and housings are positioned with high accuracy.

-

Precision assembly – The stator and rotor must be aligned to exact tolerances to prevent energy loss and reduce wear.

-

Electrical integration – Connectors, sensors, and controllers are installed with strict quality checks to ensure stable long-term performance.

-

Quality inspection – Advanced vision systems and automated testing equipment verify winding integrity, insulation resistance, and motor output parameters.

-

Final testing – Each motor undergoes dynamic load testing to simulate real-world conditions before leaving the production line.

Advantages of Automated Assembly

With the demand for electric vehicles growing rapidly, traditional manual assembly methods are no longer sufficient. Automated assembly lines bring significant advantages:

-

Consistency and precision – Robotics eliminate human error in handling delicate parts.

-

High throughput – Automated lines dramatically increase production speed to meet market demand.

-

Traceability – Digital tracking ensures each motor’s production history is recorded for quality assurance.

-

Flexibility – Intelligent lines can adapt to different motor designs, making them ideal for diverse applications in electric cars, buses, and industrial equipment.

Jieyun Intelligent Equipment (Suzhou) Co., Ltd. provides turnkey solutions for new energy drive motor assembly lines, integrating robotics, automation, and intelligent monitoring systems. Their designs prioritize efficiency, precision, and long-term reliability, helping manufacturers improve output while maintaining the highest quality standards. By focusing on innovation and customization, Jieyun delivers assembly systems that keep pace with the fast-evolving electric vehicle industry.

The new energy drive motor assembly line is the backbone of electric vehicle manufacturing. By bringing together complex components such as stators, rotors, encoders, and controllers with advanced automation technology, these lines ensure that every motor meets the strict requirements of performance and durability. With industry leaders like Jieyun Intelligent Equipment (Suzhou) Co., Ltd., the future of motor production is set to be more intelligent, efficient, and reliable.

www.gwinsys.com

Jieyun Intelligent Equipment (Suzhou) Co., Ltd.