Mechanical seals and packed seals are two common types of sealing solutions used in various industries. Both seals have their own advantages and disadvantages, and choosing the right one for your application can be a challenging task. In this article, we will compare mechanical seals and packed seals in terms of their design, performance, and maintenance requirements to help you make an informed decision.

Design:

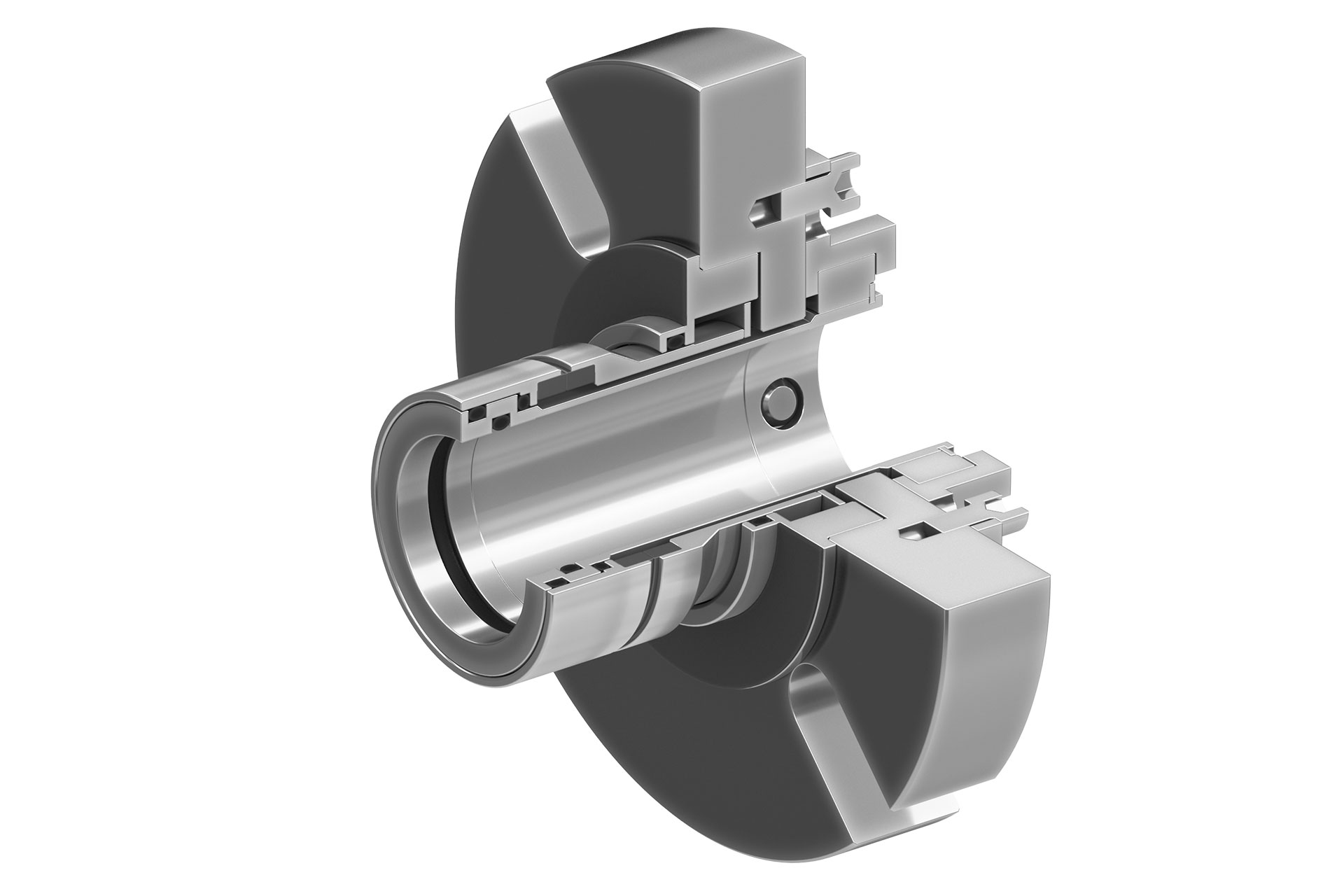

Mechanical seals consist of two flat surfaces, one stationary and one rotating, that are pressed together to create a seal. The seal faces are typically made of hard materials such as ceramic or tungsten carbide, and are lubricated by a thin film of fluid. Packed seals, on the other hand, use a soft packing material, such as graphite or PTFE, that is compressed around a rotating shaft to create a seal. The packing material is held in place by a gland, which is tightened to maintain the compression.

Performance:

Mechanical seals offer superior performance compared to packed seals in terms of leakage control and reliability. They can handle higher pressures and temperatures, and are less prone to wear and tear. Mechanical seals also require less maintenance and have a longer lifespan. Packed seals, on the other hand, are more forgiving of misalignment and shaft deflection, and are less expensive than mechanical seals.

Maintenance:

Mechanical seals require periodic maintenance, such as lubrication and replacement of worn parts. However, the frequency of maintenance is lower compared to packed seals. Packed seals require more frequent maintenance, such as adjustment of the gland, replacement of the packing material, and cleaning of the shaft. Packed seals also require more frequent monitoring to ensure that the compression is maintained.

Conclusion:

In conclusion, the choice between mechanical seals and packed seals depends on the specific application requirements. If leakage control and reliability are critical, mechanical seals are the better choice. If cost and forgiveness of misalignment are more important, packed seals may be the better option. Regardless of the choice, proper maintenance is essential to ensure optimal performance and longevity of the seal.