In the realm of industrial air movement and gas handling, the terms blower and turbo blower are frequently encountered. While both devices serve the essential function of moving air or gas, they operate on different principles and are suited for distinct applications. Understanding the differences between these two types of blowers is crucial for engineers, facility managers, and procurement specialists looking to optimize their systems for efficiency and performance. This article delves into the fundamental distinctions, operational mechanisms, and applications of blowers and turbo blowers, providing a comprehensive guide for industry professionals.

- Fundamental Definitions

Blower: A blower is a mechanical device designed to move air or gas at relatively low pressure and high volume. It typically operates using positive displacement or centrifugal force, making it suitable for various applications, including ventilation, cooling, and material handling.

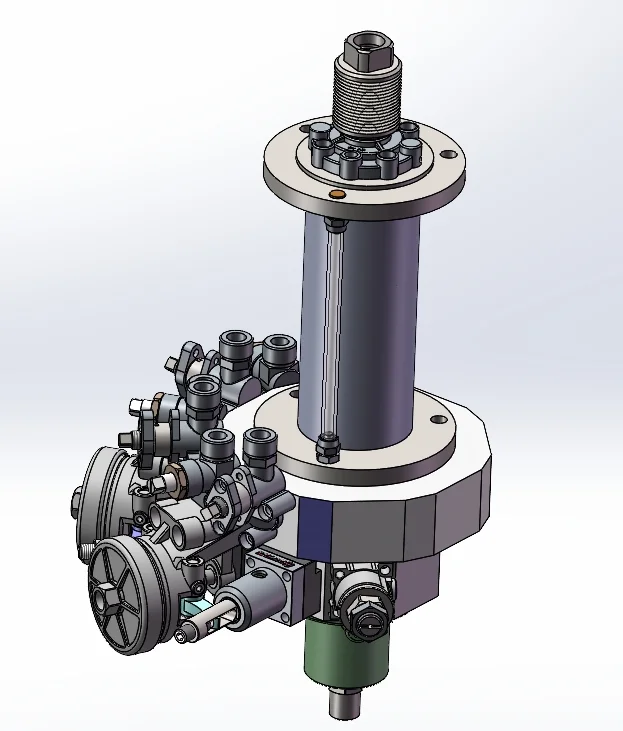

Turbo Blower: A turbo blower, on the other hand, is a specific type of centrifugal blower that utilizes a high-speed impeller to generate high-pressure air or gas. Turbo blowers are characterized by their efficiency and ability to handle large volumes of air at elevated pressures, making them ideal for applications requiring precise airflow control.

- Operational Mechanisms

2.1 Blower Mechanisms

Blowers can be categorized into two primary types: positive displacement blowers and centrifugal blowers.

- Positive Displacement Blowers: These blowers operate by trapping a fixed volume of air or gas and then forcing it out through the discharge. Common examples include rotary lobe blowers and diaphragm blowers. They are known for their ability to generate high flow rates at low pressures.

- Centrifugal Blowers: These blowers use a rotating impeller to impart kinetic energy to the air or gas, converting it into pressure. The design allows for a more compact unit compared to positive displacement blowers, making them suitable for applications where space is limited.

2.2 Turbo Blower Mechanisms

Turbo blowers employ a high-speed impeller that rotates at thousands of RPMs, creating a high-velocity airflow. The air enters the impeller and is accelerated outward, where it is then diffused to convert kinetic energy into pressure. This design allows turbo blowers to achieve higher efficiencies and lower energy consumption compared to traditional blowers.

- Performance Characteristics

3.1 Efficiency

One of the most significant differences between blowers and turbo blowers is their efficiency. Turbo blowers are designed for high efficiency, often exceeding 80-90%, particularly in applications requiring continuous operation. In contrast, traditional blowers may have lower efficiency ratings, especially under varying load conditions.

3.2 Pressure and Flow Rate

Turbo blowers excel in applications requiring high pressure and consistent flow rates. They can handle pressures up to 100 psi or more, making them suitable for demanding industrial processes. Standard blowers, while capable of moving large volumes of air, typically operate at lower pressures, making them less suitable for high-pressure applications.

- Applications

4.1 Common Applications for Blowers

- Ventilation Systems: Blowers are widely used in HVAC systems to provide ventilation and maintain indoor air quality.

- Material Handling: In industries such as food processing and packaging, blowers are employed to transport bulk materials.

- Cooling Systems: Blowers are essential in cooling applications, such as cooling towers and electronic equipment cooling.

4.2 Common Applications for Turbo Blowers

- Wastewater Treatment: Turbo blowers are commonly used in aeration processes, where they provide the necessary oxygen for biological treatment.

- Chemical Processing: In chemical manufacturing, turbo blowers are utilized for processes requiring precise airflow and high pressure.

- Power Generation: Turbo blowers are integral to gas turbine systems, where they supply compressed air for combustion.

- Conclusion

In summary, while both blowers and turbo blowers serve the essential function of moving air and gas, their operational mechanisms, efficiency, pressure capabilities, and applications differ significantly. Understanding these differences is vital for selecting the appropriate equipment for specific industrial needs. As industries continue to evolve and demand more efficient solutions, turbo blowers are increasingly becoming the preferred choice for high-pressure applications, while traditional blowers remain invaluable for low-pressure, high-volume tasks. By making informed decisions based on these distinctions, professionals can enhance operational efficiency and reduce energy consumption in their processes.