In the rapidly evolving world of energy storage, lithium batteries stand at the forefront of technological innovation, powering everything from electric vehicles to portable electronics. A critical but often under-appreciated component in these batteries is electrolytic copper foil, which serves as the primary current collector on the anode side. To optimize the performance and reliability of this material, companies around the world invest in advanced testing and research equipment — including electrolytic copper foil test lines. In this blog post, we’ll explore how these test lines accelerate lithium battery development and highlight the role played by Timonic (Suzhou) Technology Co., Ltd in this field.

What Is an Electrolytic Copper Foil Test Line?

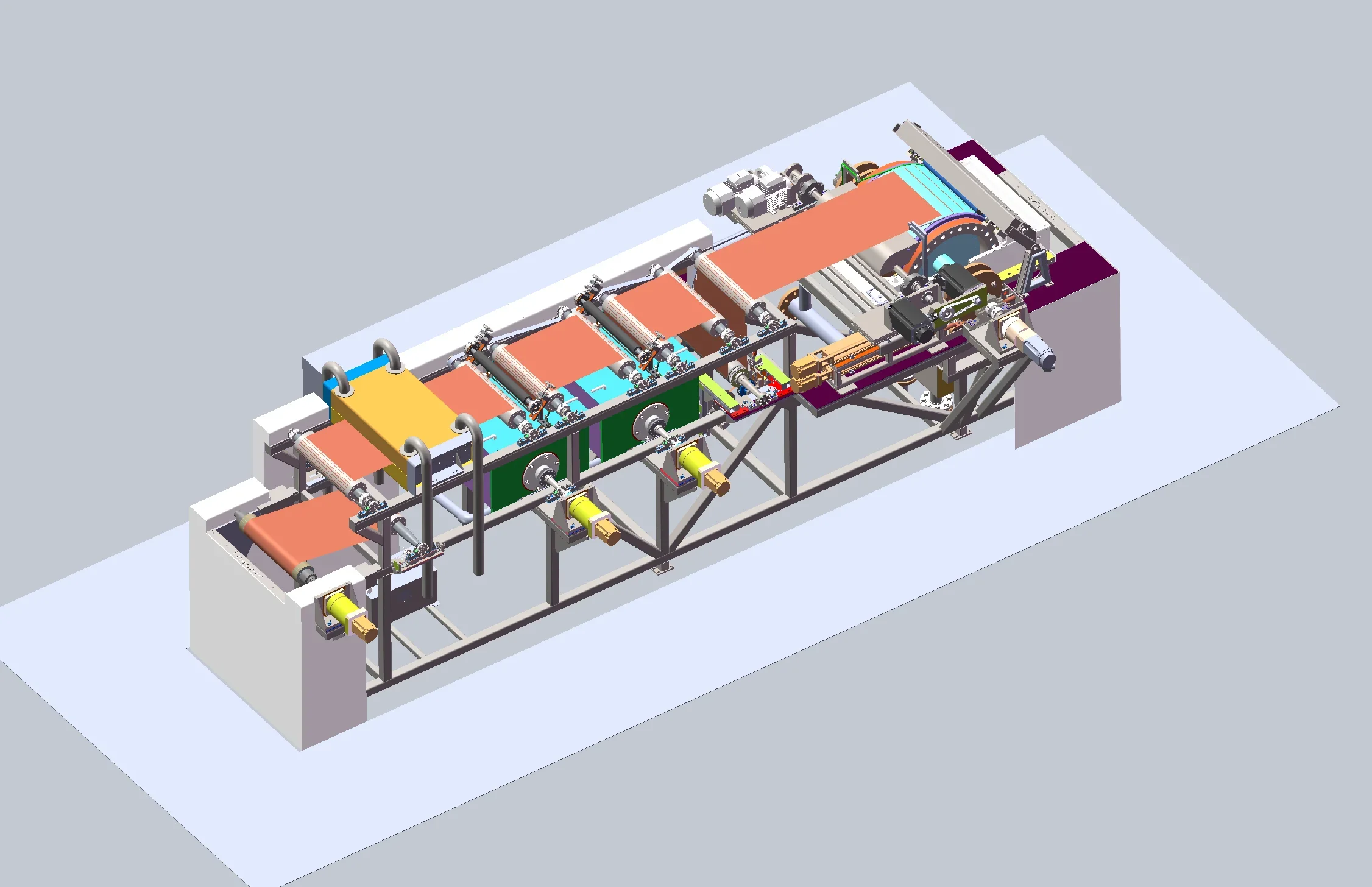

An electrolytic copper foil test line is a specialized production and research setup that simulates the continuous electrolysis process used to manufacture ultra-thin copper foils. These test lines allow researchers and engineers to:

-

Trial new production processes before scaling

-

Evaluate material performance under controlled conditions

-

Optimize key parameters such as thickness, uniformity, and mechanical properties

By integrating systems like electrolyte preparation, filtration, dosing, temperature control, and automated monitoring, test lines help ensure that copper foil meets stringent quality standards before full-scale production.

Why Copper Foil Quality Matters in Lithium Batteries

In lithium-ion battery manufacturing, copper foil plays a crucial role as a current collector for the anode. Its performance affects:

-

Electrical conductivity: Poor foil quality can increase resistance and reduce battery efficiency.

-

Cycle life: Consistent material properties help maintain capacity over many charge/discharge cycles.

-

Safety: Defects in copper foil may lead to internal short circuits, impacting safety and reliability.

The global demand for high-quality copper foil is soaring — driven by the rapid adoption of electric vehicles, grid storage systems, and portable electronics. According to recent market analysis, the electrolytic copper foil market is projected to grow substantially by 2035, propelled by demand for ultrathin foils used in advanced battery applications.

Key Applications of Electrolytic Copper Foil Test Lines

1. Process Development and Optimization

Test lines allow engineers to fine-tune electrolysis parameters such as current density, electrolyte composition, temperature, and additive dosing. These adjustments directly influence the final foil’s microstructure, roughness, and tensile strength — all of which are crucial for battery performance.

2. Material Performance Evaluation

Before committing to mass production, manufacturers use test lines to analyze copper foil behavior in simulated environments. Surface defects, thickness deviations, and mechanical properties are measured with precision tools (e.g., micrometers, XRF gauges) to ensure product reliability.

3. Innovation and New Product Trials

Researchers experimenting with next-generation lithium battery chemistries or current collector designs often start with test production runs. These controlled environments make it easier to study the effects of new alloys, coatings, or structural features without risking expensive full-scale operations.

4. Quality Control and Standard Compliance

A well-configured test line supports consistent quality control, ensuring that produced copper foil meets international standards relevant to battery manufacturing (e.g., ASTM, IEC).