In the modern automotive landscape, electronics have become a central part of vehicle functionality. As car manufacturers increasingly embrace technological advancements, the need for high-performance, compact, and durable circuit boards has never been greater. Among the most promising solutions is the use of polyimide flexible PCBs. These specialized circuit boards are not only lighter and more flexible than traditional rigid PCBs but also deliver exceptional performance and durability—key attributes for automotive instrument panels. SprintPCB leads the charge in providing polyimide flexible PCBs that meet the unique demands of the automotive industry.

Why Polyimide Flexible PCBs Are Perfect for Automotive Instrument Panels

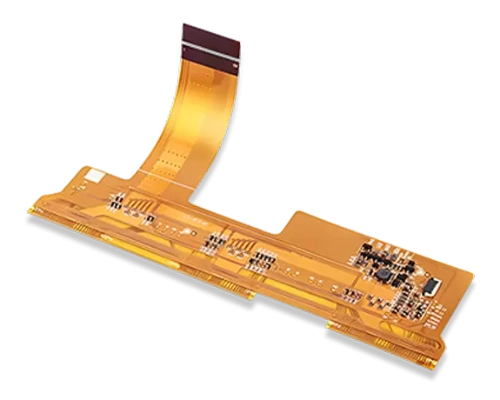

Automotive instrument panels are becoming more sophisticated, incorporating digital displays, navigation systems, sensors, and more. These systems require advanced electronics that can endure harsh conditions, fit within tight spaces, and maintain high functionality. Polyimide flexible PCBs provide the perfect solution, with several advantages over traditional PCB technology:

Space-Efficiency and Flexibility

Polyimide flexible PCBs are designed to be extremely thin and lightweight, making them an ideal choice for compact automotive applications. The flexible nature of these PCBs allows them to bend and conform to the intricate shapes and sizes required by modern vehicle dashboards. Whether it's a curved display panel or a multi-layered sensor module, polyimide flexible PCBs can be shaped to meet the design specifications of automotive instrument panels without taking up excess space.

Durability Under Extreme Conditions

Automotive environments expose electronics to high temperatures, humidity, vibrations, and physical stress. Polyimide flexible PCBs are known for their exceptional durability in these conditions. Unlike traditional rigid PCBs, flexible boards can endure constant movement, vibration, and bending without compromising their electrical integrity. This reliability makes them an excellent choice for instrument panels, which are constantly in motion and exposed to fluctuating temperatures.

Enhanced Signal Integrity

Signal integrity is crucial for automotive instrument panels that rely on precise communication between sensors and displays. Polyimide flexible PCBs are designed to reduce noise and interference, ensuring stable and reliable signal transmission. Whether it's transmitting data from a vehicle's GPS system or communicating with the dashboard's central processing unit, polyimide flexible PCBs provide consistent performance, even under dynamic conditions.

Long-Lasting Performance

The lifespan of a vehicle is typically several years, and the electronics in the instrument panel need to function reliably for the duration of the vehicle's life. SprintPCB polyimide flexible PCBs are engineered for longevity, withstanding repeated bending cycles and maintaining electrical performance without degradation. This makes them ideal for applications where long-term reliability is paramount, such as automotive instrument panels that may need to function for hundreds of thousands of miles.

SprintPCB Polyimide Flexible PCB Solutions for Automotive Electronics

As the automotive industry continues to evolve, the demand for advanced, reliable, and space-efficient electronics has become more pronounced. SprintPCB stands at the forefront of manufacturing polyimide flexible PCBs, offering innovative and customized solutions that meet the unique needs of automotive applications.

SprintPCB's Expertise in Automotive Electronics

With years of experience in designing and manufacturing PCBs, SprintPCB has developed a deep understanding of the complex demands of automotive applications. This expertise allows them to deliver polyimide flexible PCBs that are seamlessly integrated into the intricate systems of vehicle instrument panels, providing automotive manufacturers with optimized solutions for their specific needs. Whether it's creating space-efficient designs or ensuring long-lasting performance in harsh conditions, SprintPCB offers a proven track record in delivering reliable results for the automotive sector.

Advanced and Flexible Manufacturing Capabilities

SprintPCB offers a wide range of design specifications for polyimide flexible PCBs, allowing automotive engineers to develop complex circuit layouts. Their support for 1 to 6 layers enables the creation of multi-functional, high-performance circuits suitable for automotive applications. With copper thicknesses ranging from 8μm to 70μm, SprintPCB ensures an ideal balance of conductivity and flexibility for polyimide flexible PCBs, making them perfect for diverse automotive needs.

Our precision capabilities, including ultra-fine trace and gap control down to 0.05 mm, enable high-density designs that are essential for space-constrained automotive instrument panels. Additionally, advanced manufacturing processes such as laser cutting and micro milling provide exceptional dimensional accuracy, ensuring that polyimide flexible PCBs fit seamlessly within tight automotive spaces.

To guarantee long-term reliability, SprintPCB offers a variety of surface finishes, such as immersion gold and lead-free tin, ensuring solderability and durability in the harsh automotive environment. This combination of design flexibility, precision, and robust finishes makes SprintPCB polyimide flexible PCBs an excellent choice for modern automotive electronics.

Rapid Prototyping for Efficient Automotive Design

One of the standout services SprintPCB offers to automotive manufacturers is their rapid prototyping service. This feature is particularly valuable in the fast-paced automotive industry, where time-to-market is critical. SprintPCB polyimide flexible PCB allows manufacturers to quickly test their designs, iterate on them, and refine their concepts before moving to full-scale production. This reduces the development cycle for automotive instrument panels, ensuring that innovative new designs are brought to market more quickly.

Comprehensive Engineering Support Throughout the Process

SprintPCB's commitment to excellence extends beyond manufacturing; they provide comprehensive engineering support at every stage of the design and production process. From the initial concept and prototyping to full-scale production, SprintPCB's experienced engineering team works closely with automotive manufacturers to ensure that every polyimide flexible PCB meets the required functional specifications. Whether it's optimizing design for manufacturability or troubleshooting during production, SprintPCB's engineering support ensures seamless execution.

The automotive industry is rapidly evolving, and with it, the demand for more sophisticated, compact, and reliable electronics for instrument panels. Polyimide flexible PCBs have emerged as the solution to these challenges, offering lightweight, durable, and high-performance options that meet the unique demands of modern vehicles. SprintPCB is a leader in providing polyimide flexible PCBs tailored to the automotive industry, offering unparalleled manufacturing capabilities, engineering support, and rapid prototyping services. With SprintPCB's advanced solutions, automotive manufacturers can create instrument panels that are not only visually stunning but also reliable and functional, ensuring that drivers have the best experience possible.

https://www.sprintpcb.net/pcb/Flexible-PCB.html

www.sprintpcb.net

SprintPCB