In high-precision optical systems, every detail matters—from the wavelength of light to the alignment of micrometer-scale lenses. Yet one component often overlooked but absolutely vital to optical performance is the adhesive that holds these parts together. Optical adhesives are specially engineered bonding materials designed to provide excellent light transmission, mechanical stability, and environmental resistance while maintaining optical alignment and clarity. Unlike general-purpose glues or epoxies, optical adhesives are formulated to meet the exacting requirements of optoelectronic, photonic, and imaging systems. Whether it's in a smartphone camera module, an industrial laser, or a fiber optic transceiver, the quality and behavior of the adhesive layer directly influence the system’s performance. This article Peiyang explores the essential properties of optical adhesives in modern engineering.

What are Optical Adhesives?

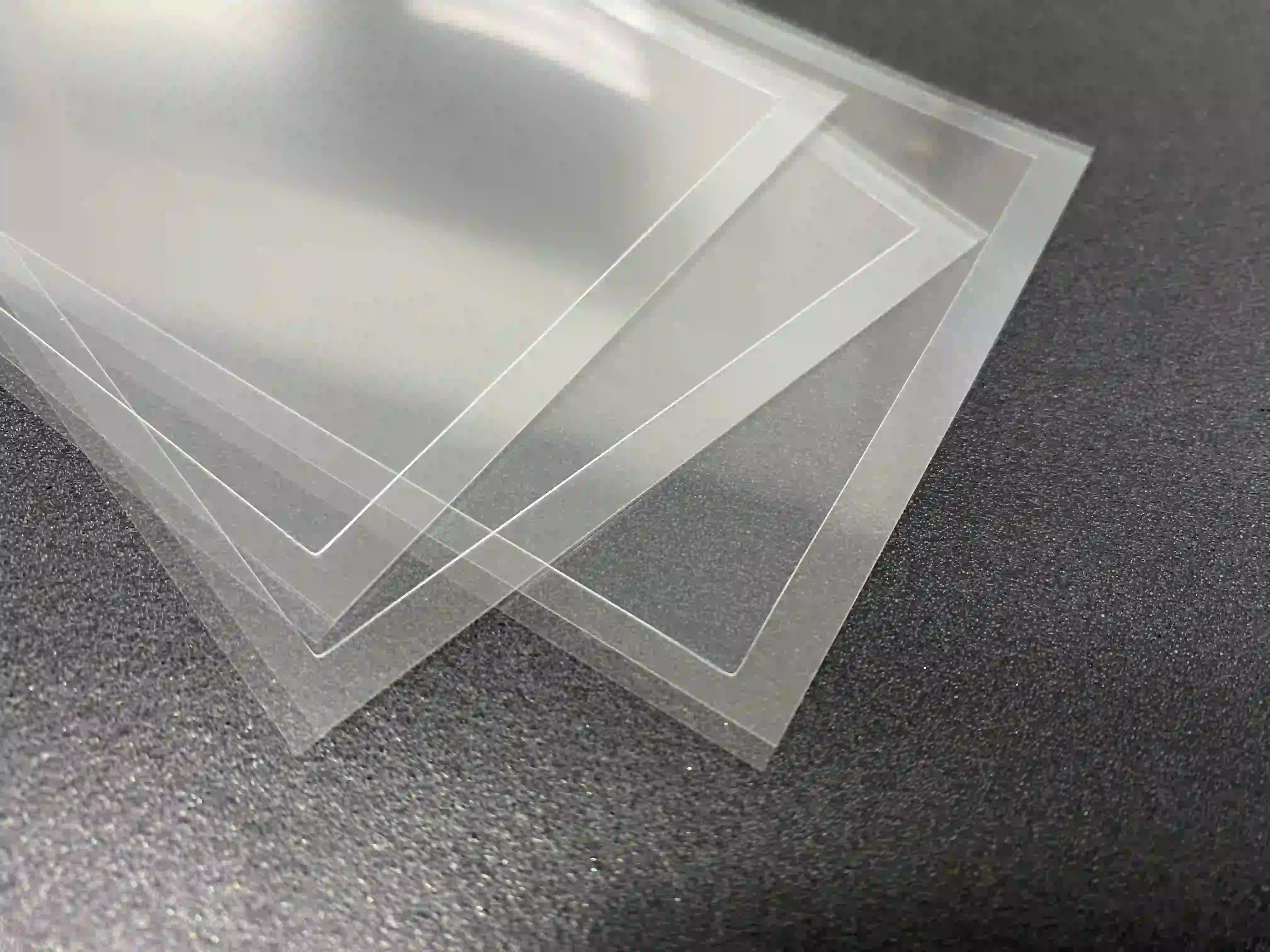

Optical adhesives are advanced bonding materials specifically engineered for assembling optical components where light transmission, precision, and durability are critical. Unlike general-purpose adhesives, optical adhesives offer exceptional optical clarity, low haze, and high light transmittance across ultraviolet, visible, or infrared wavelengths. They are designed to match the refractive index of substrates like glass, plastic, or quartz, minimizing reflection and ensuring a seamless optical path. These adhesives also exhibit low shrinkage during curing to preserve precise alignment and avoid introducing optical distortion or mechanical stress. Depending on the application, they may offer high mechanical strength, vibration resistance, UV stability, and thermal reliability across a wide temperature range. Optical adhesives are commonly used in devices such as camera modules, fiber optic connectors, AR/VR displays, medical imaging systems, automotive sensors, and aerospace instruments. Their role is vital in maintaining both the mechanical integrity and optical performance of high-precision assemblies, making them an indispensable material in modern optoelectronics and photonic engineering.

Fundamental Properties of High-Performance Optical Adhesives

Optical Clarity and High Transmission Rates

For an adhesive to be suitable in optical applications, it must be almost entirely transparent across the desired wavelength range—whether UV, visible, or IR. High-performance optical adhesives typically exhibit >90% transmittance, with minimal haze and no coloration, to ensure that the adhesive layer does not interfere with light propagation.

Furthermore, the refractive index of the adhesive must be carefully matched to that of the surrounding materials. A mismatch causes reflections and refractions at the interface, reducing image quality or signal strength. Precision bonding with optical adhesives ensures uniform optical paths and eliminates internal scattering that can degrade system resolution or brightness.

Low Shrinkage and Dimensional Accuracy

In high-precision optical devices, alignment tolerances are often within microns. Any post-curing shrinkage can lead to misalignment and performance degradation. Optical adhesives are designed with ultra-low shrinkage formulations to maintain mechanical alignment and avoid introducing stress or optical aberrations into the system. Low shrinkage is particularly crucial in bonded systems such as laser assemblies, microscopes, and interferometers where even the smallest displacement can compromise functionality.

Mechanical Strength and Flexibility

Depending on the substrate materials (glass, plastic, metal) and the operational environment, optical adhesives must exhibit strong adhesion while also accommodating slight mechanical stresses due to vibration, impact, or thermal cycling. Adhesives used in automotive optics or aerospace sensors must handle both dynamic and static stress over time without cracking or delaminating.

Some applications require rigid bonding (e.g., laser diode collimators), while others demand a degree of elasticity (e.g., curved display assemblies). The versatility of optical adhesives to serve both needs is a testament to advanced chemical engineering in adhesive design.

Resistance to Environmental Stress

Optical assemblies are often deployed in demanding environments—outdoors, under high humidity, extreme heat or cold, and constant UV exposure. Advanced optical adhesives must demonstrate high resistance to yellowing, fogging, and moisture ingress. They should retain transparency and adhesion after thousands of thermal and humidity cycles.

In cleanroom or vacuum environments such as semiconductor lithography or space telescopes, optical adhesives are required to meet low-outgassing standards (e.g., ASTM E595) to prevent contamination of optical surfaces.

From the smallest camera lens in a smartphone to the most sophisticated space telescope, optical adhesives are the invisible heroes that hold everything together—without compromising performance. They not only ensure strong, durable bonds but also protect optical pathways from environmental degradation and mechanical failure. Selecting the right optical adhesive requires a deep understanding of the application environment, substrate compatibility, curing methods, and performance goals. As devices become smaller, lighter, and more powerful, the demand for advanced optical adhesives continues to grow. Investing in high-quality, application-specific optical adhesives is not just a materials decision—it's a strategic commitment to precision, reliability, and long-term success in a competitive global market.

https://www.opticaladhesives.com/Optical-Adhesives

www.opticaladhesives.com

Suzhou PeiYang New Material Technology Co. Ltd