https://www.xinghuijm.com/cnc-pneumatic-fixture-fabrication.html

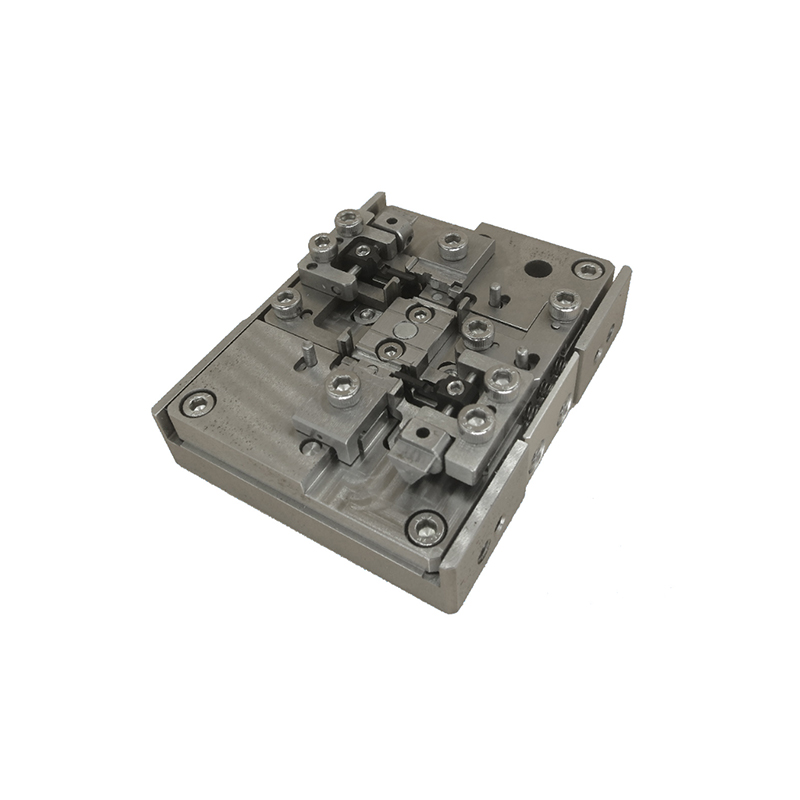

In modern manufacturing, metal structure parts fabrication demands high precision, stability, and efficiency. To achieve this, CNC pneumatic fixtures are widely used to clamp and support workpieces during machining. The choice of material for these fixtures is critical because it directly impacts machining accuracy, production efficiency, and long-term durability.

Importance of Material Selection in Metal Structure Parts Fabrication

During metal structure parts fabrication, fixtures must endure clamping forces, cutting resistance, and vibrations without deformation. If the fixture lacks strength or rigidity, the accuracy of the finished part will be compromised. Therefore, selecting the right material ensures both reliability and quality throughout the fabrication process.

Common Materials for CNC Pneumatic Fixtures

-

Aluminum Alloys

-

Advantages: Lightweight, corrosion-resistant, and easy to machine.

-

Applications: Suitable for metal structure parts fabrication involving high-speed machining or situations requiring frequent repositioning of fixtures.

Steel

-

Advantages: Superior strength, rigidity, and excellent wear resistance.

-

Applications: Best for heavy-duty metal structure parts fabrication, especially in industries that require long production runs and stable clamping under high stress.

Composite Materials

-

Advantages: High stiffness-to-weight ratio, vibration damping, and low thermal expansion.

-

Applications: Used in precision-driven metal structure parts fabrication such as aerospace, electronics, and automotive sectors.

Benefits of Choosing the Right Fixture Material

-

Higher Precision: Ensures stable clamping during metal structure parts fabrication, reducing machining errors.

-

Extended Durability: Withstands repetitive stress, minimizing downtime.

-

Improved Efficiency: Optimizes operations by maintaining stability in high-speed or heavy-load environments.

-

Cost-Effectiveness: Reduces replacement and maintenance costs over long-term use.

Industry Expertise

Shenzhen Star Precision Machinery Co., Ltd. provides custom CNC pneumatic fixtures designed specifically for metal structure parts fabrication. By combining advanced engineering with carefully selected materials like aluminum, steel, or composites, the company ensures fixtures that meet the diverse needs of modern manufacturing industries.

Material selection is a fundamental factor in CNC pneumatic fixture fabrication for metal structure parts fabrication. The right material ensures precision, efficiency, and durability, enabling manufacturers to achieve consistent results and maintain competitiveness in demanding industries. For companies looking to optimize their production lines, expertise in fixture design and material science is the key to success.

https://www.xinghuijm.com/cnc-pneumatic-fixture-fabrication.html

Shenzhen Star Precision Machinery Co., Ltd.