https://www.weiguangele.com/working-principle-behind-absolute-hollow-shaft-encoders.html

In the world of industrial automation and motion control, precision and reliability are essential. Position sensors play a crucial role in ensuring that machines, motors, and robotic systems operate accurately and consistently. Among the many sensing devices used in automation, the absolute hollow shaft encoder stands out for its ability to deliver exact position information, even after power loss, while maintaining a compact, space-efficient structure.

Developed and produced by Jilin Weiguang Electronic Technology Co., Ltd., this advanced encoder combines the advantages of absolute positioning technology with a hollow shaft design to provide accurate, stable, and flexible motion feedback for a wide range of applications.

1. Working Principle of the Absolute Hollow Shaft Encoder

An absolute encoder differs fundamentally from an incremental encoder in how it measures and transmits position data. Instead of generating pulse signals that count relative movement, an absolute encoder assigns a unique digital code to every position along its measurement range.

This means that each angular position corresponds to a specific binary or Gray code value, which can be read directly by the control system. As a result, even if power is lost or the system is restarted, the encoder can immediately report the exact position without requiring a homing or reset procedure.

This “absolute positioning” capability is vital in high-precision systems where position loss can cause mechanical errors, downtime, or safety risks — such as in robotics, CNC machines, servo drives, and elevator control systems.

2. Advantages of the Absolute Encoding Method

-

Non-volatile position memory: The encoder retains accurate position information even after a power outage. There’s no need to reinitialize the machine’s zero point.

-

Error-free startup: Eliminates cumulative errors common in incremental encoders that rely on counting pulses.

-

High resolution and repeatability: Depending on the design, absolute encoders can achieve resolutions of up to 18–22 bits or more, enabling fine control of motor speed and position.

-

Robust data output: Many models support digital communication protocols such as SSI, CANopen, Modbus, or Profibus, allowing seamless integration into modern automation systems.

These advantages make absolute encoders ideal for applications demanding consistent accuracy and long-term reliability under continuous operation.

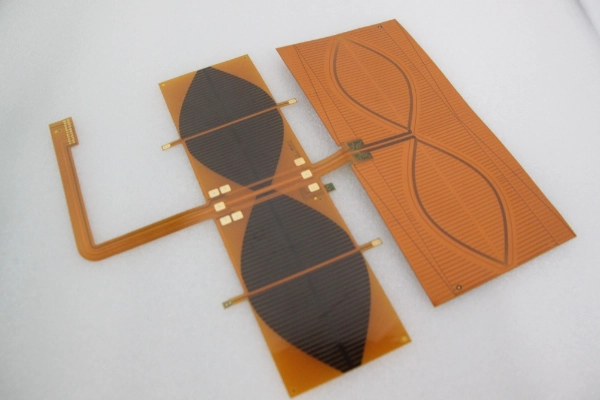

3. Hollow Shaft Design — Space Efficiency and Integration

The hollow shaft structure is a key feature that enhances the encoder’s usability and flexibility. Unlike solid-shaft encoders, a hollow shaft encoder allows the motor shaft or other rotating component to pass directly through the center of the device.

This design offers several major benefits:

-

Compact installation: The encoder can be mounted directly on the end of a motor or transmission shaft, minimizing additional mechanical components such as couplings or brackets.

-

Space-saving integration: Especially valuable in compact equipment, the hollow shaft design reduces the overall footprint and simplifies system layout.

-

Easy maintenance: With fewer mechanical connections, alignment errors and wear points are reduced, improving long-term stability.

-

Improved mechanical efficiency: The direct coupling between the encoder and shaft ensures better signal accuracy and eliminates backlash caused by additional mechanical parts.

Some hollow shaft encoders also feature clamping rings or set screws that allow quick installation and easy adjustment without special tools, making them ideal for tight industrial environments.

www.weiguangele.com

Jilin Weiguang Electronic Technology Co., Ltd.