In industrial fluid handling systems, valves play a vital role in controlling the flow of liquids, gases, and slurries. Among various valve types, the stainless steel butterfly valve has gained popularity across multiple industries due to its durability, corrosion resistance, and compact design. Whether used in chemical plants, water treatment facilities, or food processing lines, stainless steel butterfly valves offer an efficient and reliable solution for flow regulation.

In this article, we explore the top six advantages of using stainless steel butterfly valves in industrial applications and why sourcing them from trusted suppliers like Yuanjian Metal Materials ensures superior performance and reliability.

1. Excellent Corrosion Resistance

Stainless steel is known for its high resistance to corrosion, especially in aggressive environments involving chemicals, saltwater, or high humidity. Stainless steel butterfly valves are ideal for applications in:

-

Chemical processing

-

Marine and offshore platforms

-

Food and beverage facilities

With materials like 304 or 316 stainless steel, these valves offer long-term protection against rust, oxidation, and pitting—ensuring a longer service life even in harsh conditions.

2. Compact and Lightweight Design

Compared to other valve types like gate or globe valves, butterfly valves are more compact and lightweight. This makes them easier to install, especially in systems where space is limited or weight is a concern—such as elevated pipelines or mobile equipment.

The streamlined design also reduces the overall cost of pipe support structures and installation labor, leading to better project efficiency.

3. Fast Operation and Flow Control

Stainless steel butterfly valves operate using a quarter-turn mechanism, allowing for quick opening and closing. This feature is especially beneficial in systems that require rapid flow control or emergency shut-off.

Additionally, butterfly valves can be used for throttling applications, providing adjustable control over the flow rate—ideal for industrial processes requiring flexibility.

4. Low Maintenance Requirements

Thanks to the durability of stainless steel and the valve’s simple mechanical structure, stainless steel butterfly valves require minimal maintenance. Their design reduces the risk of clogging or wear and allows for easy cleaning, making them perfect for industries with high hygiene standards like:

-

Food processing

-

Pharmaceuticals

-

Water purification

By choosing high-quality materials from suppliers like Yuanjian Metal Materials, end users benefit from enhanced valve longevity and lower total cost of ownership.

5. High Temperature and Pressure Tolerance

Stainless steel butterfly valves can withstand higher temperatures and pressures compared to plastic or cast iron counterparts. This makes them suitable for demanding industrial applications such as:

-

Steam systems

-

Hot water pipelines

-

High-pressure chemical transport

Their strength under stress helps maintain safety and system stability even in critical environments.

6. Versatility Across Industrial Applications

The adaptability of stainless steel butterfly valves makes them suitable for a wide range of uses, including:

-

Oil and gas pipelines

-

HVAC systems

-

Mining and slurry transport

-

Power generation plants

With options for different valve seat materials, actuator types, and flange standards, these valves can be customized to meet specific operational requirements.

Why Choose Yuanjian Metal Materials?

As a professional stainless steel product supplier, Yuanjian Metal Materials provides not only stainless steel butterfly valves, but also a full range of high-quality stainless steel materials such as:

-

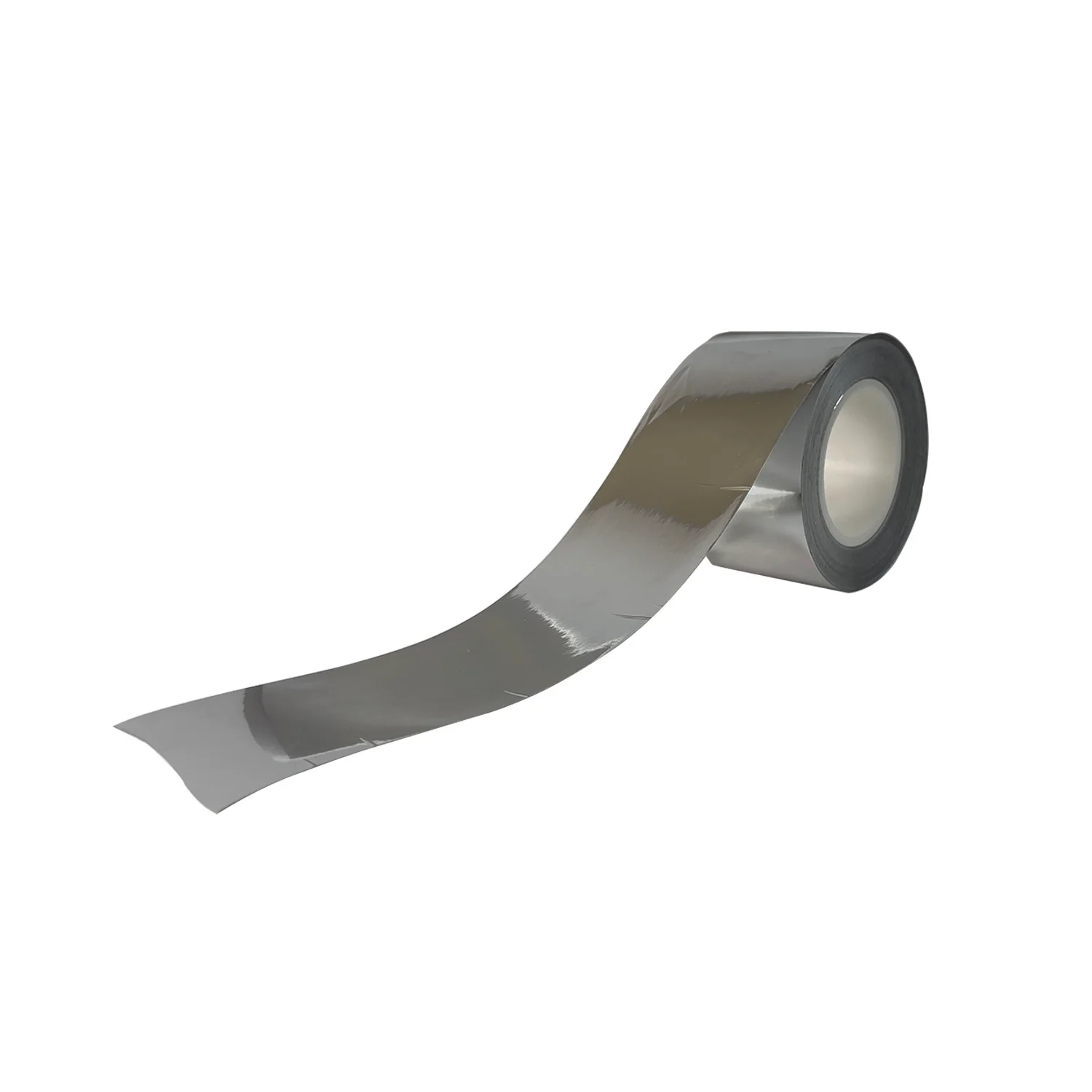

Steel plates and coils

-

Steel pipes and pipe fittings

-

Round bars, hex bars, and square bars

-

Custom flanges and components

With an annual production capacity exceeding 200,000 tons, Yuanjian supports industrial projects with consistent quality, customizable solutions, and fast delivery. Whether you need raw materials or finished components, Yuanjian ensures that your stainless steel products meet industry standards and your specific application needs.

Final Thoughts

For engineers, contractors, and procurement managers, choosing stainless steel butterfly valves is a smart investment in performance, reliability, and longevity. These valves provide versatile and efficient flow control in demanding environments and require minimal upkeep over time.

When sourcing stainless steel valves or raw materials, partnering with a trusted supplier like Yuanjian Metal Materials guarantees access to top-tier products and customized support—helping your industrial systems operate at peak performance.

Looking for high-quality stainless steel valves or components?

Get in touch with Yuanjian Metal Materials today to find the best solution for your project needs.

www.visionstainless.com

Wuxi Yuanjian Metal Materials Co., Ltd.