In industries where heat exchange is a critical part of the manufacturing process, the need for durable and efficient equipment is paramount. Heat exchangers are integral components in many industrial applications, helping to regulate temperature, conserve energy, and ensure the smooth operation of machinery. Among the different materials used in the construction of heat exchangers, tantalum has emerged as a standout choice, particularly in environments that demand high resistance to corrosion and wear. The tantalum tube heat exchanger offers a range of advantages that make it ideal for such applications. In this article, Qiwei will explore the key features of the tantalum tube heat exchanger in modern industries, emphasizing its significance in environments where other materials may fail.

What are Tantalum Tube Heat Exchangers?

A heat exchanger is a device used to transfer heat between two or more fluids. These fluids can be liquids, gases, or a combination of both. The primary purpose of a heat exchanger is to either heat or cool a fluid while maintaining the integrity of the fluid flow. Heat exchangers are employed in various industries, including chemical processing, power generation, oil refining, HVAC (heating, ventilation, and air conditioning), and many others.

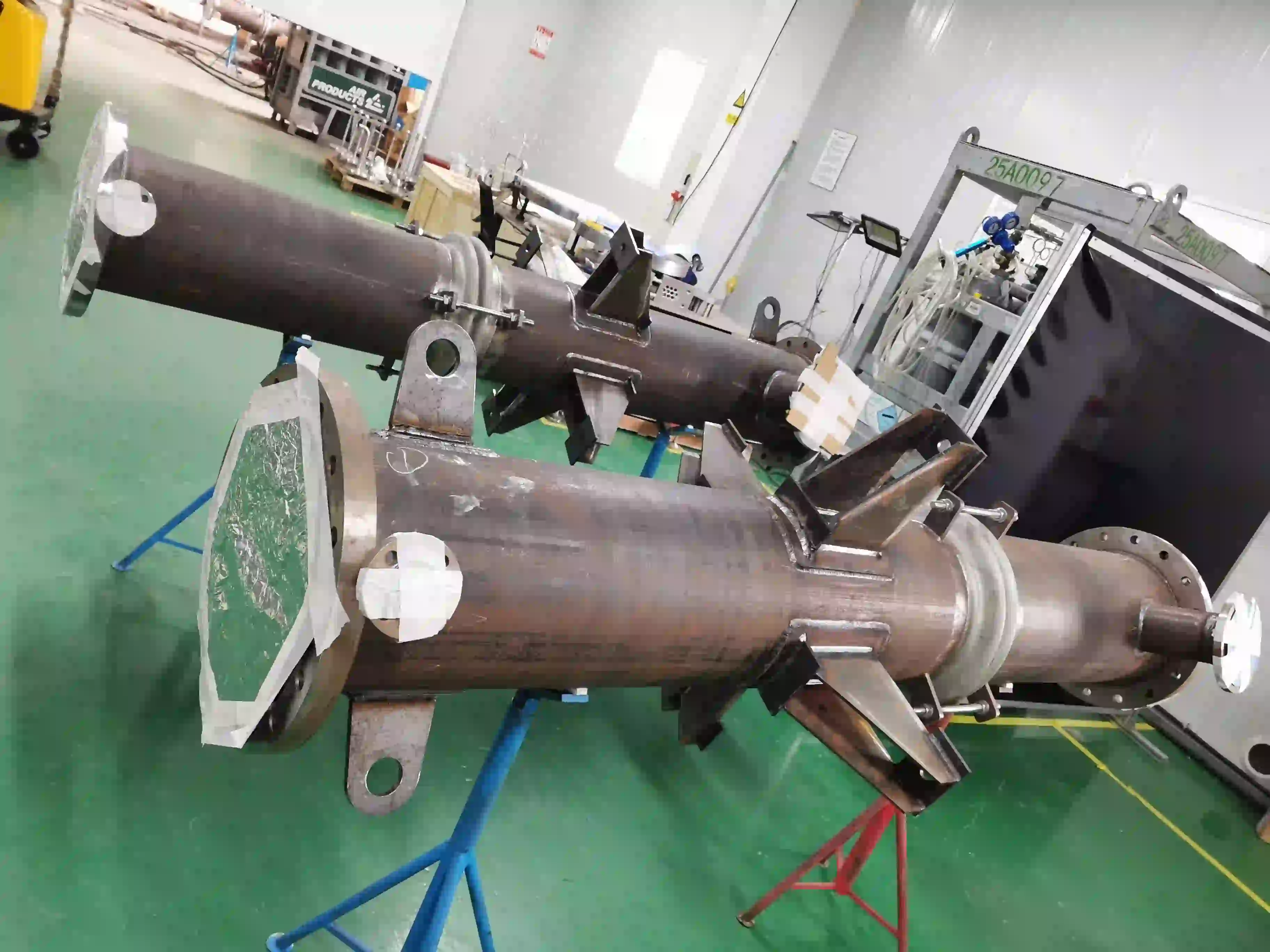

The tantalum tube heat exchanger is a specialized type of heat exchanger where the tubes, which carry the fluid that needs to be heated or cooled, are made of tantalum. Tantalum is a transition metal known for its exceptional resistance to corrosion and high melting point. These properties make tantalum ideal for heat exchangers that are used in aggressive environments, where other metals would degrade or fail.

In a tantalum tube heat exchanger, fluid flows through tubes made of tantalum, while another fluid (typically a coolant or heating fluid) flows around the tubes. The heat is transferred through the walls of the tantalum tubes, either heating or cooling the fluid inside, depending on the design. The advantage of using tantalum as the material for the tubes lies in its resistance to corrosion, which is particularly important when dealing with highly acidic or aggressive fluids, such as those found in the chemical, pharmaceutical, and petrochemical industries.

Key Features of Tantalum Tube Heat Exchangers

Several features make tantalum tube heat exchangers stand out in industries requiring superior material properties for extreme conditions. These features include their corrosion resistance, mechanical strength, and longevity.

1. Corrosion Resistance

One of the most notable features of a tantalum tube heat exchanger is the material's exceptional resistance to corrosion. Tantalum is highly resistant to a wide range of aggressive chemicals, including acids such as sulfuric acid, hydrochloric acid, and nitric acid, as well as other corrosive fluids. This resistance is due to the formation of a stable and protective oxide layer on the surface of the tantalum metal, which prevents further corrosion. In industries such as chemical processing, pharmaceuticals, and petrochemicals, where equipment is exposed to harsh chemicals, the corrosion resistance of tantalum tubes ensures the longevity and reliability of the heat exchanger. Tantalum's resistance to pitting, crevice corrosion, and stress corrosion cracking makes it particularly valuable in these applications.

2. High-Temperature Tolerance

Tantalum is known for its high melting point, which is around 3,017°C (5,463°F). This high-temperature tolerance means that tantalum tube heat exchangers can operate in environments where high heat transfer rates are required, without the risk of deformation or failure due to thermal stress. This property makes tantalum an ideal choice for heat exchangers used in high-temperature applications, such as in power generation, nuclear reactors, and metal processing. Tantalum's ability to maintain structural integrity under extreme temperatures ensures that the heat exchanger can handle thermal cycling and high-temperature processes without deteriorating over time. As a result, tantalum tube heat exchangers offer exceptional durability and efficiency, even in demanding conditions.

3. Mechanical Strength and Durability

Beyond its corrosion resistance and high-temperature performance, tantalum is also known for its excellent mechanical strength. This includes both tensile strength and hardness, which are crucial for maintaining the integrity of the heat exchanger under high-pressure conditions. Tantalum's mechanical properties ensure that the heat exchanger can handle the stresses of high-pressure environments without cracking, warping, or failing.

In industries that require the circulation of fluids under high pressure, such as in chemical reactors or industrial cooling systems, the strength of tantalum tubes plays a vital role in maintaining system reliability. The durability of tantalum tube heat exchangers reduces the need for frequent maintenance or replacement, thus offering long-term cost savings.

4. Thermal Conductivity

Tantalum has good thermal conductivity, although not as high as some other metals like copper or aluminum. However, its superior resistance to corrosion and ability to withstand extreme temperatures more than compensates for its relatively lower thermal conductivity. In heat exchanger applications, this property ensures that heat is efficiently transferred through the tantalum tubes without compromising the material's structural integrity.

The tantalum tube heat exchanger stands as a critical component in industries that demand robust, reliable, and high-performance heat exchange systems. With its unparalleled resistance to corrosion, ability to withstand high temperatures, and mechanical strength, tantalum is the material of choice for heat exchangers used in harsh and demanding environments. As industries continue to push the boundaries of technological advancements and efficiency, tantalum tube heat exchangers will undoubtedly remain an essential part of the infrastructure that supports modern industrial applications. Their performance, durability, and resistance to extreme conditions make them an indispensable asset in the world of heat exchange.

https://www.tnztn.com/Tantalum-Tube-Heat-Exchanger-A-Game-Changer-in-Corrosive-Environments.html

https://www.tnztn.com/Tantalum-Heat-Exchanger-F-7.html

www.tnztn.com

Wuxi Qiwei Nonferrous Technology Co., Ltd.