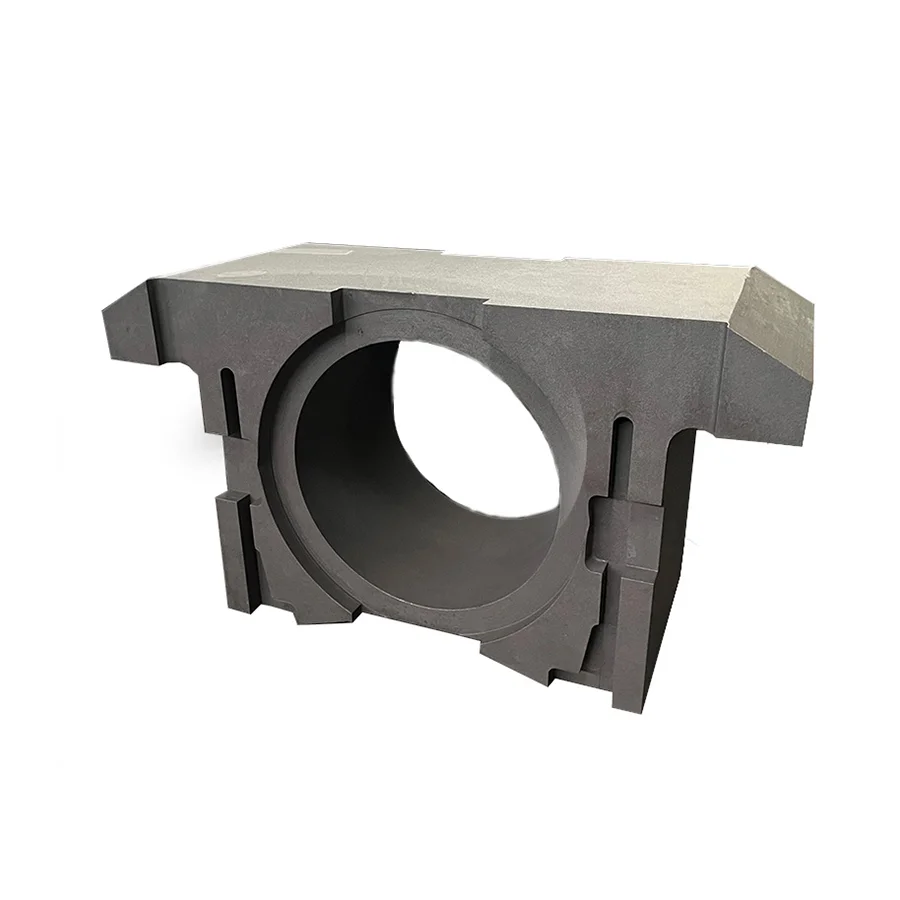

In a rolling mill, the “big forces” everyone talks about don’t magically disappear into the machine frame. They travel—through the roll, into the shaft, through the bearings, and finally into the structure that carries and distributes those loads. That structure is the rolling mill bearing housing.

For vertical roll stands in particular, the bearing housing is more than a box around a bearing. It is an essential load path component: it supports the roll shaft, maintains alignment, protects the bearing environment, and transmits rolling force reliably during continuous operation. When it performs well, the mill runs smoothly with stable product quality. When it doesn’t, problems show up quickly as vibration, heat, leakage, uneven wear, and unplanned downtime.

What the bearing housing does in real mill operation

A good bearing housing has three jobs that matter on the shop floor:

-

Support the roll shaft consistently

The housing positions the bearing so the roll axis stays where it should be, even under fluctuating load. That “staying put” is what keeps your stand stable and your rolling gap predictable. -

Transmit rolling force into the stand structure

Rolling force has to go somewhere. The housing provides a controlled path so that load transfers through designed contact surfaces instead of turning into stress concentrations, fretting, or random deformation. -

Protect the bearing system and its lubrication

Bearings don’t like contamination—especially in harsh mill environments with scale, water, heat, and fine particles. The housing is a barrier system: sealing, lubrication routing, and protective geometry all sit here.

Why vertical roll applications raise the bar

Vertical roll stands often see conditions that punish weak housings:

-

High impact and shock loads during bite-in and thickness changes

-

Thermal cycling from process heat and coolant exposure

-

Misalignment sensitivity, where small errors lead to big vibration

-

Wet/dirty environments that accelerate seal failure and bearing damage

In short: the housing must be stiff enough to hold alignment, but also designed in a way that manages load transitions and protects the bearing environment.

Common failure patterns and what they usually mean

When a mill has repeated bearing or stand issues, the root cause is often related to housing fit, sealing, or load transfer surfaces—not the bearing itself. Here are the “symptoms → likely causes” patterns buyers and maintenance teams see most:

-

Recurring bearing overheating

-

poor lubrication path, contaminated grease/oil, damaged seals, or housing distortion causing preload

-

Vibration or chatter marks on product

-

alignment drift, worn seat surfaces, looseness between housing and stand, or uneven load distribution

-

Frequent seal leakage / water ingress

-

seal design mismatch, worn seal grooves, surface finish issues, or pressure wash damage

-

Abnormal wear on housing bores or bearing seats

-

poor fit tolerance, inadequate hardness, poor surface finish, or assembly practices (over-torque, misfit)

If you treat these issues as “just replace the bearing,” you usually pay twice: first in parts, then in downtime.

A practical checklist for specifying a bearing housing

If you’re sourcing or upgrading rolling mill bearing housings, focus on details that impact uptime:

Load & rigidity

-

What rolling force does the stand see at peak?

-

Is the housing designed to prevent deformation at the bearing seat?

Alignment control

-

How is the housing located relative to the stand?

-

Are locating surfaces protected from fretting and wear?

Bearing seat & tolerance

-

Does the bore/seat finish support stable bearing fit?

-

Is there a plan for refurbishing seats after long service?

Sealing and contamination control

-

What contaminants are present (scale, water, emulsions)?

-

Does the seal system match your washdown and coolant reality?

Lubrication routing

-

Where does lubricant enter and exit?

-

Are passages protected from blockage and contamination?

Maintainability

-

Can seals be replaced without full disassembly?

-

Is the design friendly to fast changeover during planned maintenance?

This is where a “parts-only” purchase often fails. A housing works best when its design choices match the mill’s real operating environment.

How to reduce downtime with better housing strategy

If downtime is costly in your plant (it usually is), you can treat bearing housing selection as a reliability project, not a single spare part.

1) Standardize where you can

If multiple stands use similar housings, standardizing seal kits, fasteners, and lubrication interfaces reduces inventory and speeds repair.

2) Plan for wear surfaces

Seats and contact faces are wear items over time. The best supply strategy includes:

-

clear inspection criteria

-

repair methods (re-machining or sleeves where appropriate)

-

defined replacement thresholds

3) Fix the “system,” not the part

If you have repeating failures, address:

-

contamination source

-

seal protection

-

installation and alignment procedures

-

lubrication consistency

The housing sits at the center of all four.

Where SAWEI Accessories & Spare Parts Solutions fits in

SAWEI Accessories & Spare Parts Solutions, established by Jiangsu Sawei Equipment Technology Co., Ltd., positions itself as a full-chain accessories solution platform serving industries like metallurgy, cement building materials, fertilizer production, shipping, and heavy industry.

Their framing is realistic: accessories—especially moving parts—are a major part of operating cost. One accessory can solve one visible problem, but a durable solution usually comes from engineer-to-engineer communication, followed by evaluation, technical improvement, and coordinated changes that unlock efficiency across the whole system.

For a bearing housing project, that “solution approach” typically means looking beyond the drawing and asking:

-

What is the failure mode in your mill?

-

What is the contamination and lubrication reality?

-

What is the maintenance pattern and changeover constraint?

-

What should be improved in fit, sealing, and load path?

That’s how you move from repeated replacement to stable reliability.

Buyer takeaway

A rolling mill bearing housing is not a commodity block of metal. In a vertical roll stand, it is a precision load path component that directly affects alignment, bearing life, and rolling stability. If you treat it as a system interface—load, fit, sealing, lubrication, and maintainability—you get longer service cycles and fewer surprises.

www.swasps.com

Jiangsu Sawei Equipment Technology Co., Ltd.