In modern industrial applications, material performance is critical for safety, longevity, and efficiency. One material that stands out for its strength, reliability, and insulating properties is the 3240 fiberglass sheet. Known for its exceptional durability and electrical insulation, this material is widely used in electrical engineering, industrial manufacturing, and construction projects.

PT. UNIKATAMA INDO PERKASA, a leading supplier of industrial materials, emphasizes the importance of using high-quality fiberglass sheets to ensure product performance and safety.

What are 3240 Fiberglass Sheets?

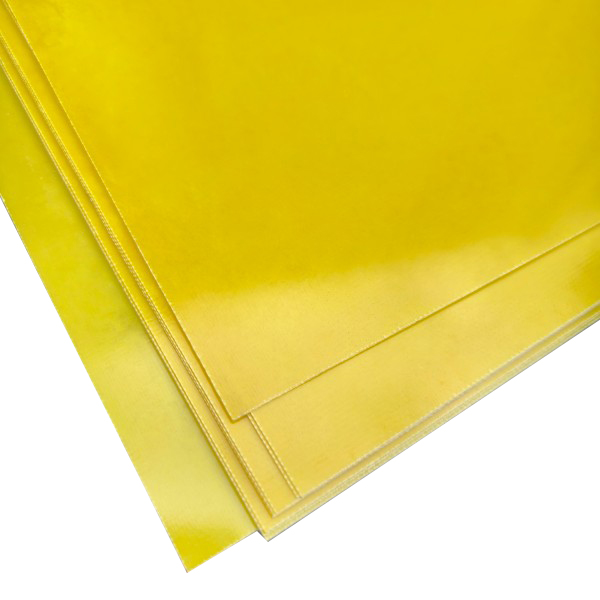

Fiberglass sheets are composite materials made from woven glass fibers embedded in a resin matrix. The 3240 fiberglass sheet is a specialized grade designed to offer superior mechanical strength, thermal stability, and electrical insulation. These sheets combine lightweight characteristics with resistance to chemical, mechanical, and environmental stresses, making them ideal for demanding applications.

Key features include:

High Mechanical Strength: Resists bending, cracking, and impact damage.

Excellent Electrical Insulation: Protects sensitive components from electrical faults.

Thermal Stability: Maintains integrity under high temperatures.

Corrosion and Moisture Resistance: Suitable for humid or chemically aggressive environments.

Dimensional Stability: Minimal expansion or contraction under changing conditions.

These features make 3240 fiberglass sheets a reliable choice in industrial and electrical applications.

Enhancing Durability in Industrial Applications

Durability is essential for materials exposed to mechanical stress, environmental conditions, or heavy usage. 3240 fiberglass sheets excel in maintaining long-term structural integrity.

1. Mechanical Strength and Impact Resistance

The woven glass fibers in 3240 fiberglass sheets provide reinforcement, preventing cracks or breakage under pressure. This makes them ideal for applications such as:

Industrial Work Surfaces: Machines and equipment bases that require strong, stable platforms.

Protective Panels: Guarding electrical or mechanical components against accidental impact.

Structural Supports: Lightweight yet strong supports for machinery, conveyor systems, and enclosures.

By resisting bending and deformation, 3240 fiberglass sheets reduce maintenance costs and extend the life of installed components.

2. Thermal and Chemical Resistance

Fiberglass sheets maintain performance under high temperatures and exposure to chemicals, oils, or solvents. This is particularly important in industrial environments:

High-Temperature Equipment: Insulation panels or supports near heat-generating machines.

Chemical Processing: Components in contact with solvents, acids, or cleaning agents.

Outdoor Installations: Sheets exposed to UV radiation, humidity, or rain.

This resistance ensures that installations remain durable over time, even under challenging conditions.

Electrical Insulation Benefits

Electrical insulation is a primary advantage of 3240 fiberglass sheets, making them suitable for applications where safety and performance are critical.

1. High Dielectric Strength

3240 fiberglass sheets offer excellent dielectric strength, preventing electrical leakage and reducing the risk of short circuits. This makes them ideal for:

Electrical Panels and Switchboards: Separating components and preventing electrical contact.

Transformers and Circuit Boards: Providing insulation in high-voltage environments.

Motor and Generator Components: Ensuring safe operation of rotating electrical machinery.

By maintaining consistent electrical insulation, these sheets protect both equipment and personnel.

2. Moisture and Chemical Resistance

Moisture can significantly reduce the insulating properties of many materials. 3240 fiberglass sheets resist water absorption, maintaining electrical performance in humid environments. Additionally, they resist chemical corrosion, preventing degradation that could compromise insulation.

Industrial Control Panels: Safe operation even in damp conditions.

Outdoor Electrical Enclosures: Reliable insulation under rain or humidity exposure.

Laboratory and Processing Facilities: Protection against chemical splashes or cleaning agents.

This combination of mechanical and electrical resilience ensures reliable performance across applications.

Applications Across Industries

The versatility of 3240 fiberglass sheets makes them suitable for a wide range of industrial and electrical applications.

1. Electrical and Electronics Industry

3240 fiberglass sheets are widely used in:

Insulating panels for switchgear and distribution boards.

Base materials for printed circuit boards (PCBs).

Spacers and supports for transformers and high-voltage equipment.

2. Industrial Manufacturing

In manufacturing, durability and heat resistance are critical. Applications include:

Protective covers and panels for machinery.

Conveyor system guides and supports.

Custom industrial components requiring high strength and minimal deformation.

3. Construction and Structural Applications

Fiberglass sheets are lightweight, durable, and resistant to corrosion, making them suitable for:

Cladding and protective panels.

Reinforced surfaces in humid or chemical-prone areas.

Lightweight support structures where metal may corrode or conduct electricity.

By integrating 3240 fiberglass sheets, engineers and designers can improve safety, durability, and performance in diverse projects.

Installation and Maintenance Tips

To maximize the performance of 3240 fiberglass sheets:

Proper Cutting and Handling: Use recommended cutting tools to prevent splintering or fraying.

Secure Mounting: Ensure panels are firmly fixed to avoid vibration or movement.

Avoid Sharp Impacts: While sheets are strong, repeated heavy impacts can compromise integrity.

Regular Cleaning: Use mild detergents; avoid harsh chemicals that may degrade resin.

Storage Conditions: Store sheets flat in a dry environment to maintain dimensional stability.

Following these best practices helps preserve mechanical strength and electrical insulation properties.

Conclusion

3240 fiberglass sheets are an exceptional material choice for industrial and electrical applications. Their combination of high durability, thermal and chemical resistance, and superior electrical insulation makes them suitable for demanding environments. By selecting quality materials like 3240 fiberglass sheet from PT. UNIKATAMA INDO PERKASA, manufacturers, engineers, and designers can ensure long-lasting performance, enhanced safety, and reduced maintenance in their projects.

Whether used in electrical panels, industrial machinery, or structural applications, 3240 fiberglass sheets provide a reliable solution for modern industrial needs.

www.unikatamaindo.com

PT. UNIKATAMA INDO PERKASA