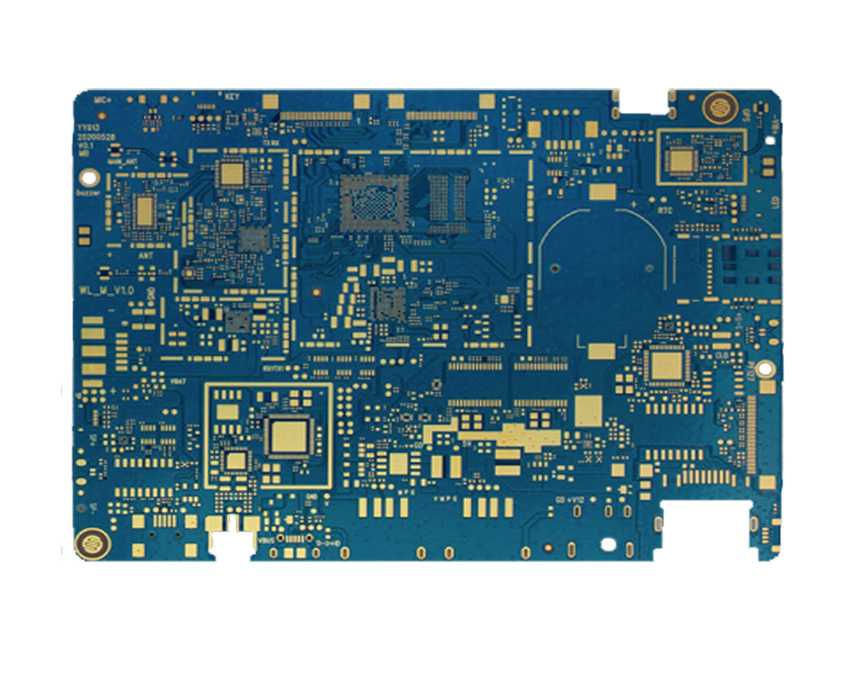

High frequency printed circuit boards (PCBs) are essential for modern electronic devices that require fast signal transmission, low loss, and high reliability. These PCBs are used in advanced technologies such as 5G communication, radar systems, satellite devices, and high-speed digital circuits. Designing and manufacturing high frequency PCBs demand precision, expertise, and advanced materials.

Shenzhen ZinPon Electronics Co., Ltd is a leading and reliable printed circuit board (PCB) manufacturer specializing in high frequency, high-speed, and multilayer PCBs. With years of experience and advanced production capabilities, the company provides high-quality PCB solutions to customers worldwide.

Understanding High Frequency PCBs

High frequency PCBs operate at frequencies above 1 GHz and require materials that maintain stable dielectric properties and low signal loss. Unlike standard FR4 boards, these PCBs typically use specialized materials such as Rogers, Taconic, or PTFE substrates. These materials ensure consistent performance and signal integrity in high-speed applications.

When selecting materials, engineers must consider dielectric constant (Dk), dissipation factor (Df), and thermal stability. These factors significantly affect impedance control and overall signal transmission quality.

Key Design Considerations for High Frequency PCBs

Designing a high frequency PCB involves more than just layout. Here are the crucial elements that influence performance:

1. Controlled Impedance

Impedance must remain consistent along signal paths to minimize reflections and losses. Careful calculation of trace width, spacing, and dielectric thickness is essential.

2. Signal Integrity and Crosstalk Reduction

Proper grounding, layer stack-up design, and isolation between high-speed traces help reduce crosstalk and interference. Using microstrip or stripline structures ensures better signal control.

3. Material Selection and Thermal Management

The choice of material influences dielectric stability, loss tangent, and heat dissipation. PTFE-based laminates and low-loss materials are ideal for RF and microwave circuits.

4. Via and Transmission Line Design

Minimizing via count and optimizing transition design reduces signal distortion. Controlled impedance vias and back-drilling techniques are often used to enhance performance.

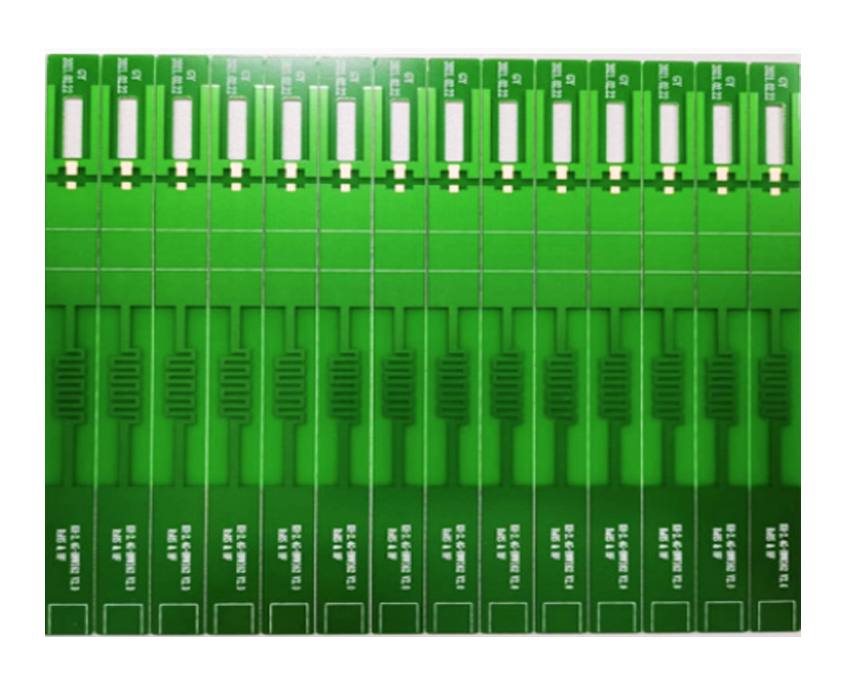

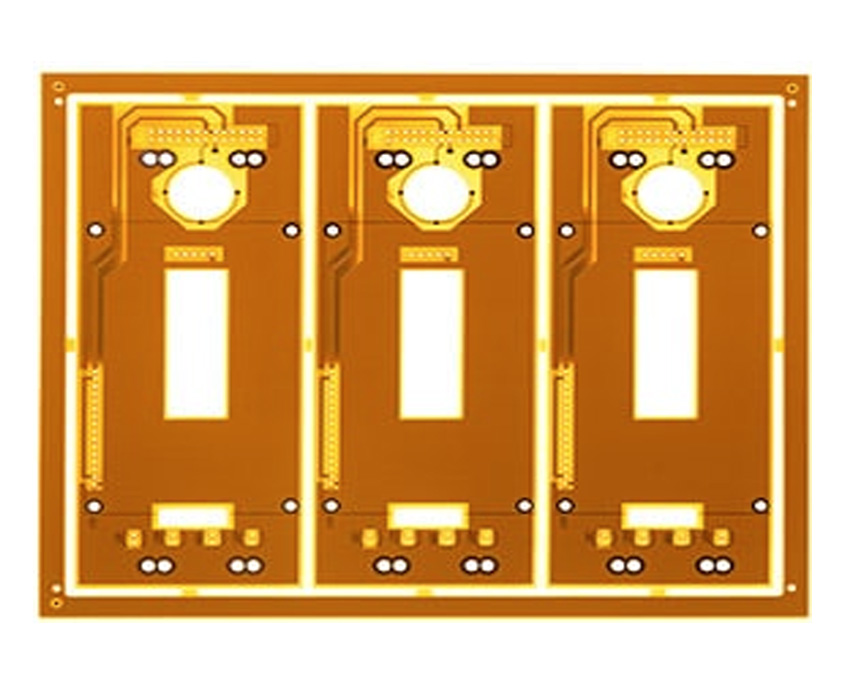

The Manufacturing Process of High Frequency PCBs

The manufacturing process for high frequency PCBs requires precision and advanced equipment. Shenzhen ZinPon Electronics Co., Ltd follows strict quality control and industry standards throughout each step:

Material Preparation: The selected high-frequency laminates are cut, cleaned, and prepared to prevent contamination that could affect signal quality.

Inner Layer Imaging: Fine-line imaging ensures precise circuit patterns using advanced photolithography.

Lamination and Drilling: Controlled lamination conditions and high-accuracy drilling machines are used to maintain signal integrity and layer alignment.

Plating and Etching: Chemical plating and etching processes define the copper traces with minimal deviation.

Solder Mask and Surface Finish: Protective coatings such as ENIG or immersion silver enhance solderability and long-term performance.

Testing and Quality Assurance: ZinPon conducts 100% electrical testing and impedance verification to guarantee functionality and reliability.

Common Applications of High Frequency PCBs

High frequency PCBs are critical in industries where fast and stable signal transmission is mandatory. Key applications include:

-

5G base stations and antenna systems

-

Automotive radar and advanced driver-assistance systems (ADAS)

-

Satellite communication equipment

-

RF and microwave amplifiers

-

Medical imaging and diagnostic devices

These demanding applications rely on precise design and manufacturing to achieve consistent performance and low noise.

Why Choose Shenzhen ZinPon Electronics Co., Ltd

Shenzhen ZinPon Electronics Co., Ltd stands out as a trusted partner for high frequency PCB design and manufacturing. The company offers:

-

Expertise in multilayer, HDI, and RF PCB production

-

Use of advanced materials from Rogers, Taconic, and Isola

-

Fast prototyping and flexible manufacturing capabilities

-

Strict quality management with ISO and UL certifications

-

Global delivery and reliable technical support

With a commitment to excellence and innovation, ZinPon Electronics ensures every PCB meets international performance and reliability standards.

Conclusion

Designing and manufacturing high frequency PCBs requires deep understanding, precise engineering, and reliable production capabilities. From selecting the right materials to implementing controlled impedance designs, every step affects the final performance.

Partnering with a professional manufacturer like Shenzhen ZinPon Electronics Co., Ltd ensures high-quality results, efficient production, and long-term reliability for your advanced electronic projects.

Whether you need prototypes or mass production, ZinPon Electronics delivers world-class PCB solutions tailored to your high-frequency applications.

Exploring the Applications of High Frequency PCBs in Communication and Radar Systems

www.zinponpcb.com

Shenzhen Zinpon Electronics Co, Ltd.